Hydro-Thermal is the world leader in development and the manufacture of Hydroheaters (also known as Jetcookers). With more than 80 years of experience serving the following industries: ethanol and starch, food and beverage, chemistry, pulp and paper, metal and other industries.

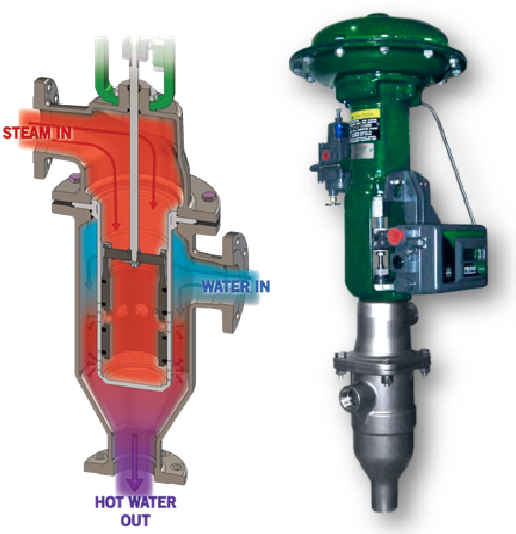

Hydro-Thermal heaters use direct steam injection (DSI). Mixing steam directly with process fluids or slurries is ideal for heating liquids in a wide range of viscosities and solid content at precise temperatures, while transferring 100% of steam’s latent and sensible energy.

Hydroheater®

- (Also known as Jetcooker ™) Heats a wide range of liquids, from water to high viscosity slurries

- Flowrate working range: 0,2 to 1.522 m3/h

- Uses: pulp and paper industry applications, biofuels, ethanol and starch conversion, high volume water, anaerobic digestion, cooking and more

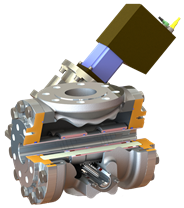

Solaris®

- Optimized direct heater, handles high viscosity slurries and/or with a higher solids content.

- Flowrate working range: 1 to 5.678 m3/h

- Viscosities up to 40.000 cP

- Uses: pulp and paper industry, bleaching, anaerobic digestion and other fibrous suspensions.

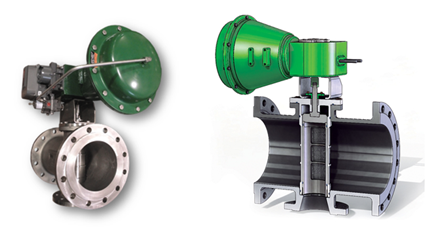

Noh (Non-obstructing heater)

- Robust, capable of handling abrasive materials (such as sand or grit) or materials with large particles/fibers

- Flowrate working range: 6,8 to 689 m3/h

- Uses: pulp bleaching, cellulosic ethanol, meat paste, chopped and scalded vegetables, mining and metals, municipal and industrial wastewater and in-line water heating with a large temperature increase.

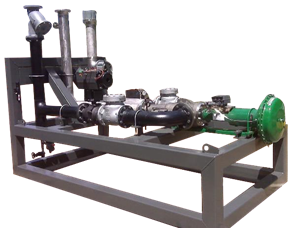

ATTEC® System

ATTEC Skids or Advanced Fluid Heating Skids are fully customized solutions that are designed, built and installed to individual specifications. Hydro-Thermal will provide the necessary components, including piping and control systems. These skids can be used to process any type of paste, including starch cooking, food manufacturing, chemical processing and everything in between.

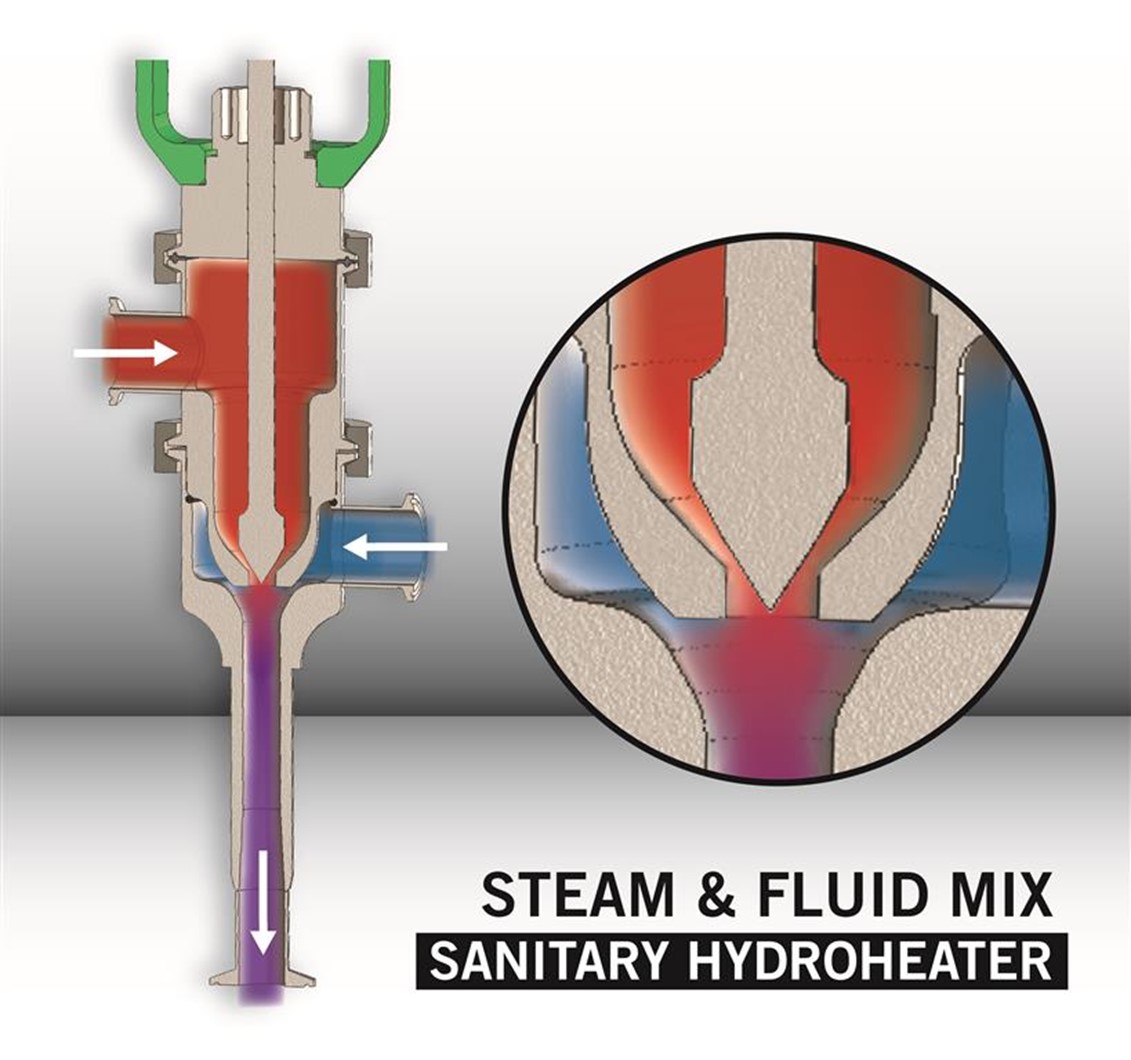

Sanitary Hydroheater®

- The patented 3A certified heater made of stainless-steel heats a wide range of liquids from water to high viscosity slurries.

- Flowrate working range: 0,2 to 41 m3/h

- Uses: cooking food and beverages, cheese and dairy production, sauces and pharmaceutical fluids.

SiverLine™ Smart Cooking System

- CE-certified, FDA-compliant and sanitary 3A-certified system made of stainless steel for starches, slurries and products with high solids content

- Flowrate working range: 1,1 to 45 m3/h

- Uses: soups, sauces, beverages, dairy products, tomato-based products, starch-based products, high or low shear products, pasteurization, batch processing or continuous.

EZ Heater®

- Only for hot water

- Flowrate working range: 0,5 to 306 m3/h

- Uses: Heating/filling tanks, washing, Clean in Place (CIP), sanitation, washing canned cans and chemical reactors

EZ Skid™ System

- For hot water only, uses the EZ Heater®

- Flowrate working range: 0,5 to 306 m3/h

- Uses: Heating/filling tanks, washing, Clean in Place (CIP), sanitation, washing canned cans and chemical reactors