This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

DeltaMem AG was founded through a Management Buy-Out of Sulzer’s Membrane Technology business including the membrane team having long standing experience in the membrane separation field. Deltamem has a team with more than 35 years of experience in the field of membrane technology. Present in research and development activities and innovative solutions of engineering plants with the aim of becoming a first-class innovation partner for sectors, such as pharmaceutical, chemical and food.

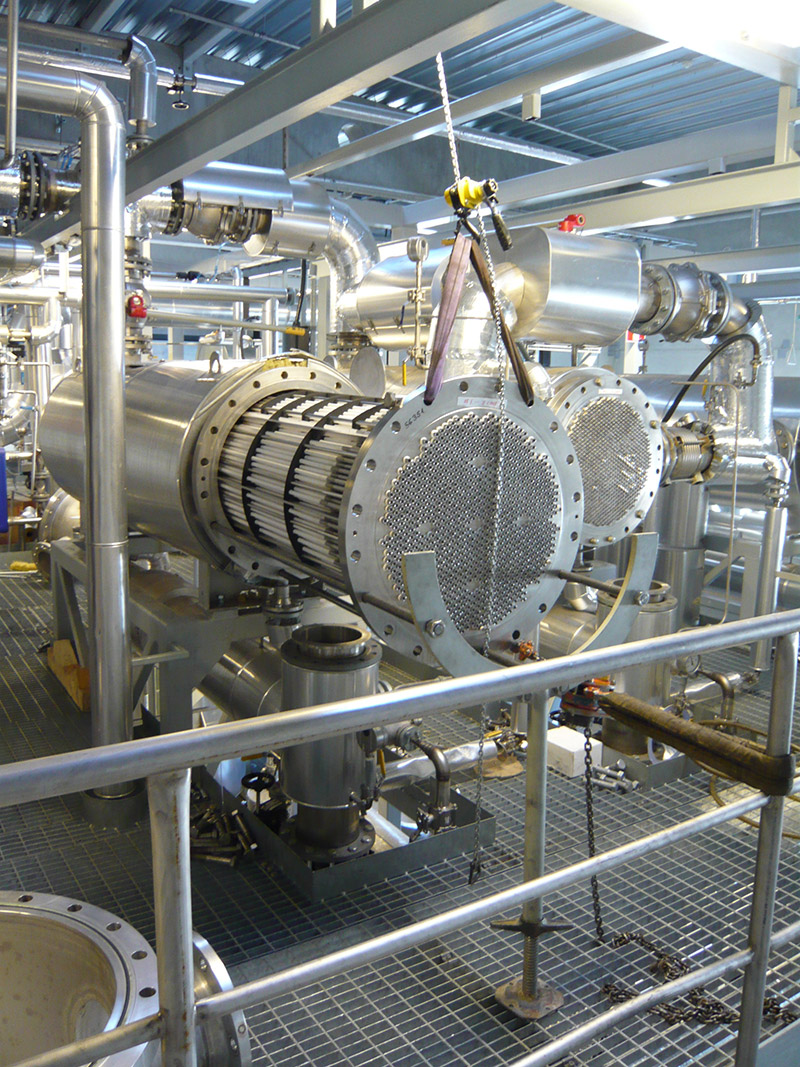

DeltaMem AG has in its references the largest pervaporation and steam permeation facility in the world.

MEMBRANES FOR PERVAPORATION AND VAPOUR PERMEATION

Pervaporation is a thermal membrane separation process which can be used to remove water or methanol from organic solvents.

The pervaporation process requires neither regeneration nor the introduction of an additional fluid. Therefore, further separation steps and environmental impact are avoided.

PERVAP™ MEMBRANE

DeltaMem has a proprietary range of PERVAP™ polymer composite membranes in its portfolio.

DeltaMem’s PERVAP™ polymeric membranes for dehydration and methanol removal is based on polyvinyl alcohol (PVA) separation layer.

The separation layer is cross-linked in different ways to produce a range of hydrophilic membranes suitable for different pervaporation and vapor permeation applications.

DeltaMem also offers also world class inorganic pervaporation membranes.

MEMBRANE MODULES: POLYMERIC AND CERAMIC

Skid-mounted construction is one of the most efficient and cost effective methods of construction. The advantages can include: