This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

The generation of vacuum, compression and impulsion of different gases is a frequent application at industrial plants. The liquid ring technology is consolidated as one of the most efficient for its robustness and performance for most processes.

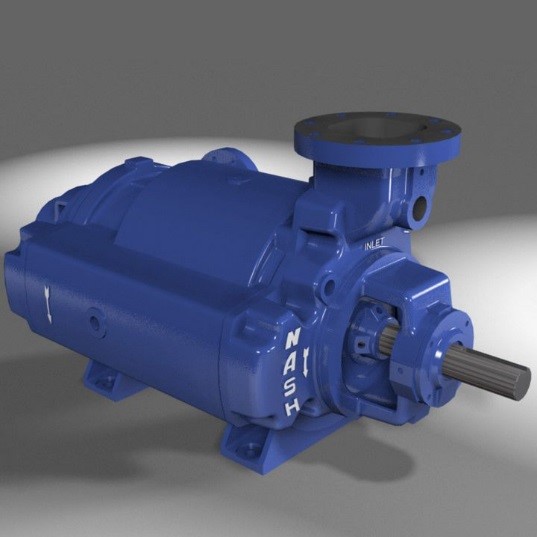

NASH products are designed to cover a wide range of applications, from chemical and petrochemical sectors to pharmaceutical and food. NASH can supply the necessary product in each case.

Garden Denver NASH is, in short, a recognized leader in the supply of air and gas compression technologies, vacuum generation and fluid transfer in the global process industry, with more than 150 years of experience in the manufacture of this equipment.

Dry vacuum pumps

The NASH DRY-PRO is a line of pumps and dry vacuum systems very simple, but sophisticated, reliable and highly efficient. The dry and contact-free operation does not require lubrication in the pumping chamber. This translates into important advantages: no contamination of the process and no pollution caused by the operation of the pump.

The DRY-PRO VSA models offer screw rotors with fixed pitch, low noise levels, easy design for maintenance, and a combination of mechanical seal and PTFE double lip seal, to ensure maximum sealing of the shaft.

Available in corrosion-resistant versions, the DRY-PRO VSA is suitable for solvent recovery and drying processes in the plastics industry, as well as for other chemical and pharmaceutical applications.

DRY-PRO VSB models offer screw rotors with a variable pitch, low noise levels, easy to service design and a combination of mechanical and double-lip PTFE seals to assure maximum shaft tightness.

Available in corrosion resistant and ATEX compatible versions, the DRY-PRO VSB is suitable for solvent recovery and drying processes in chemical and pharmaceutical applications.

Capacity: 80 to 650 m3 / h

Vacuum: at 0.03 mbar (a)

Certification: ATEX versions available

Additional capacity can be achieved through of the use of high vacuum impellers.

Liquid ring vacuum pumps

NASH offers reliable, quality liquid ring vacuum pumps with the features and performance needed for the most demanding applications.

Información general:

Some examples of the wide range of vacuum pumps that NASH has is its portfolio (to learn more, go to the NASH webpage):

Double stage liquid ring vacuum pump NASH model TC/TCM

The NASH TC two stage liquid ring vacuum pump series offers highly reliable and efficient solutions for power, chemical and petrochemical applications. Designed to handle large amounts of liquid carryover without difficulty.

The integral two stage impeller is designed to reach vacuum levels to 20mmHgA, approximately 40% lower absolute pressure than a single stage pump. The design, small and compact, is easy to maintain, with both rotors in the same body. The rotor blades are designed and installed to improve resistance and reliability.

In chemical and petrochemical applications, TC / TCM pumps condense process steam and recover it or dispose of it.

At power generation plants, the NASH TC / TCM two-stage pumps are the core of our condenser extraction systems. The TC / TCM conical port design works with a condenser cooled by water to increase capacity and efficiency. Anti-cavitation technology (patent pending) is available on select models, and it can double the life of the pump in operations prone to cavitation.

Liquid ring vacuum pump NASH model VECTRA GL / XL

The NASH Vectra was designed around a modular platform, using the most advanced computer helped design techniques, such as 3D modeling and finite element analysis (FEA). The modular platform offers the advantage of two versions, with numerous common parts.

The Vectra GL model, available from 200 to 1,500 m³ / h, is ideal for general industrial applications. The standard model comes with internal mechanical seals and many Nash patented innovations, including gas sweeping.

The Vectra XL model was designed to accomplish the strict requirements of many CPI applications. Whether operating as a vacuum pump or compressor, it has a differential capacity of 2 bar. It is available in ductile iron or 316L stainless steel, with a variety of shaft sealing options. The sizes vary from 200 to 9,000 m³ / h.

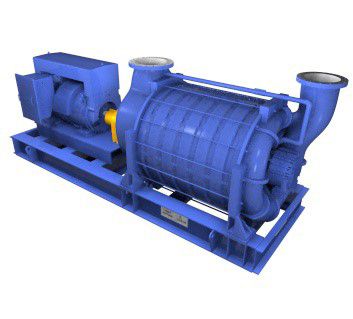

Liquid ring vacuum pump NASH model 2BE3 y 2BE4

The series of pumps and compressors NASH 2BE3 and 2BE4 offers capacities ranging from 2,500 to 33,000 m³ / h.

Designed to operate in demanding environments such as paper mills, thermal power plants, mining and chemical process industries, these pumps offer durability and reliability at low operating costs. Each model is equipped with an optimized and tested corrosion and erosion resistant coating of polyisoprene.

The single input configuration allows both the top and side entry arrangements for low-rise installations. In installations where space is limited, the upper discharge capacity of the 2BE4 allows the use of a space-saving top-mounted discharge separator, and it eliminates the need for a trench.

The 2BE3 and 2BE4 models allow an efficient operation in the entire vacuum range without the need to change the internal parts of the pump. When equipped with a central cover, a vacuum operation divided up to a differential of up to 400 mbar can be carried out. Large inspection ports allow easy access to the pump internals for inspection and maintenance.

For more aggressive applications, stainless steel components are available, coated with epoxy or coated with stainless steel.

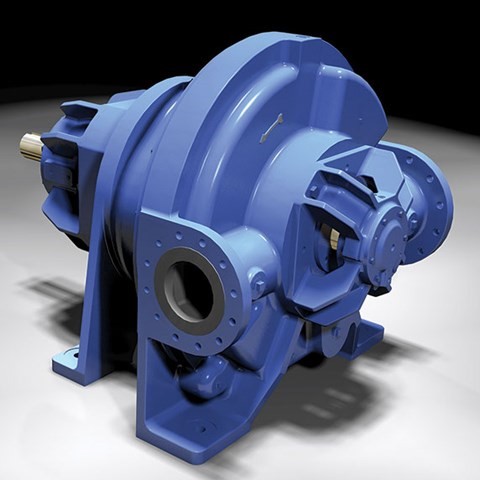

Liquid ring compressors

NASH liquid ring compressors are the robust and reliable solution for demanding process applications. NASH compressors are designed to handle highly toxic, explosive and corrosive gases, and have a reliable performance record under demanding conditions, with no downtime for repairs or rebuilds. Through on-going research and product development, we continue to produce quality liquid ring compressors, and product upgrades that excel under the most demanding conditions, while reducing the total cost of ownership.

Some examples of compressor models from the NASH range are as follows (for more information, visit NASH page):

Compressor NASH Model HP-9

This robust and reliable compressor is found mainly in petroleum refineries and chemical plants, highly toxic, explosive and corrosive gases in applications such as the recovery of combustion gases, chlorine and vinyl chloride monomer (VCM).

Along with the NASH GARO and other NASH liquid ring compressors, the NASH HP-9 compressor, the complete line of NASH compressor products, provides compression above 15 bar abs. The low pressure compressors are available for 3 Bar abs and 34,000 m³ / h. As a result, NASH offers the widest range of pressure and capacity liquid ring compressors available worldwide.

Specifications:

Suction capacity: from 3,000 to 4,300 m3 / h.

Discharge pressure: 8 bar

Mechanical Seal: Single, Double, Cartridge

Building materials: Stainless steel, other optional materials.

Compressor NASH Model Vectra XM-50

This robust and reliable liquid ring compressor expanded the range of NASH Vectra compressors with a model that works up to 4 bar G.The XM-150 comes in versions 681 and 682, and it is specifically designed for the highest pressures and performance requirements found in many process applications, including steam recovery, flare gas recovery, biogas, waste management corrosive gases (eg, VCM and chlorine), and hydrogen compression.

The NASH Vectra XM-150 Liquid Ring Compressor offers the following features: single and conical port design; simple sealing point; compliance with API-681 and API-682 category II / III; longer life of the bearings; 316 stainless steel construction; horizontal self-draining inlet / discharge nozzles.

The rugged construction and easy-to-service design of this liquid ring compressor reduce maintenance requirements and minimize downtime, even in the most demanding applications.

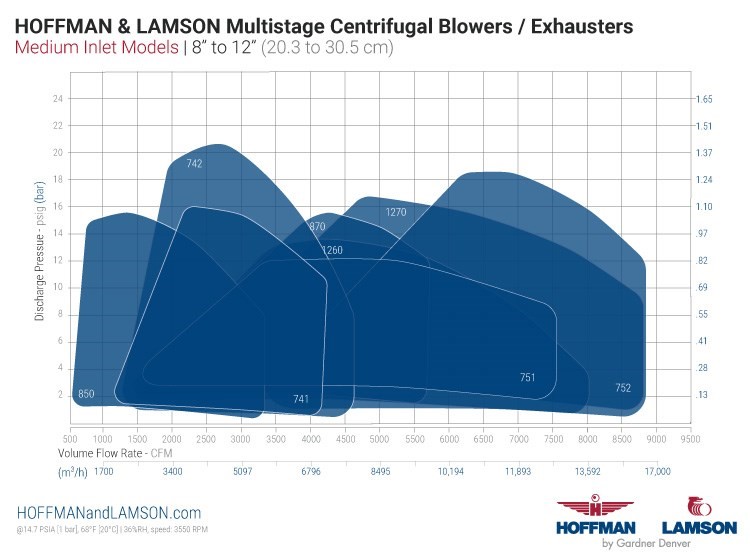

Multi-stage centrifugal blowers (Hoffman & Lamson)

The Gardner Denver NASH group manufactures, through Hoffman & Lamson, multi-stage centrifugal blowers for water treatment applications, where large amounts of air are required.

– Air volume displaced up to 69,600 m3 / h.

– Pressure up to 2.5 Bar abs.

– Empty up to 417 mbar abs.

The Hoffman and Lamson blowers provide variable flow at constant pressure, which makes them the first choice for a large number of applications in a wide range of different industries, including ventilation, extraction, material transport and drying.

We offer our customers a large number of additional design options, such as special coatings, alternative materials, lubrication with oil or grease, special seals and coupling options.

SOME USUAL APPLICATIONS OF CENTRIFUGAL BLOWERS OF MULTIPLE STAGES:

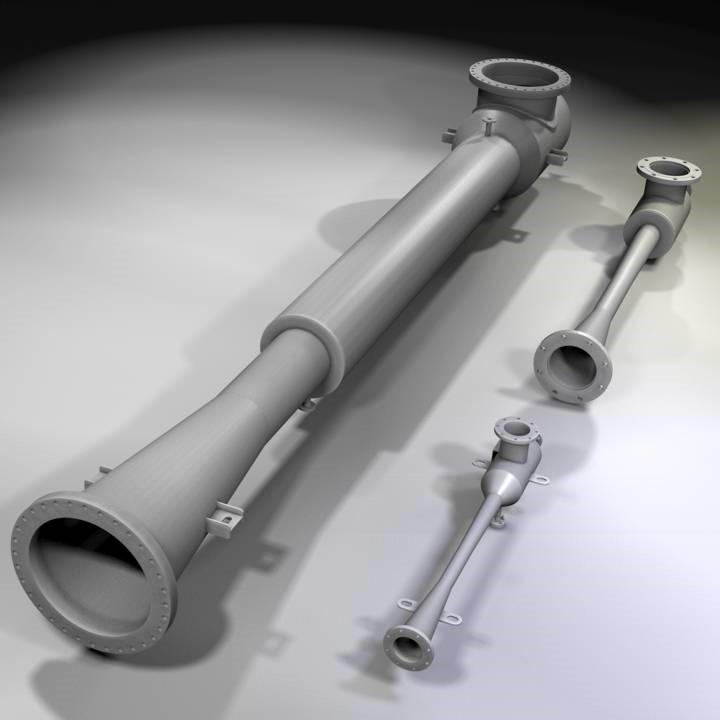

Steam ejectors

NASH air and steam ejectors provide vacuum for many process industries and utility companies in general. Nash has designed and manufactured systems with ejectors since 1986, when Nash acquired the Kinema Corporation. Either on their own, or as part of a NASH hybrid vacuum system, our air jet and steam ejectors are designed for optimum efficiency while maintaining their ability to handle large volumes at very high vacuum levels.

NASH STEAM EJECTORS: