BHS has specialized in cake filtration for more than 60 years. We supply a broad range of products for both batch and continuous processes. BHS filters for the separation of solids and liquids are used daily in different applications by more than 1000 customers around the world. All BHS filters are characterized by the fact that they work with a comparatively thin cake.

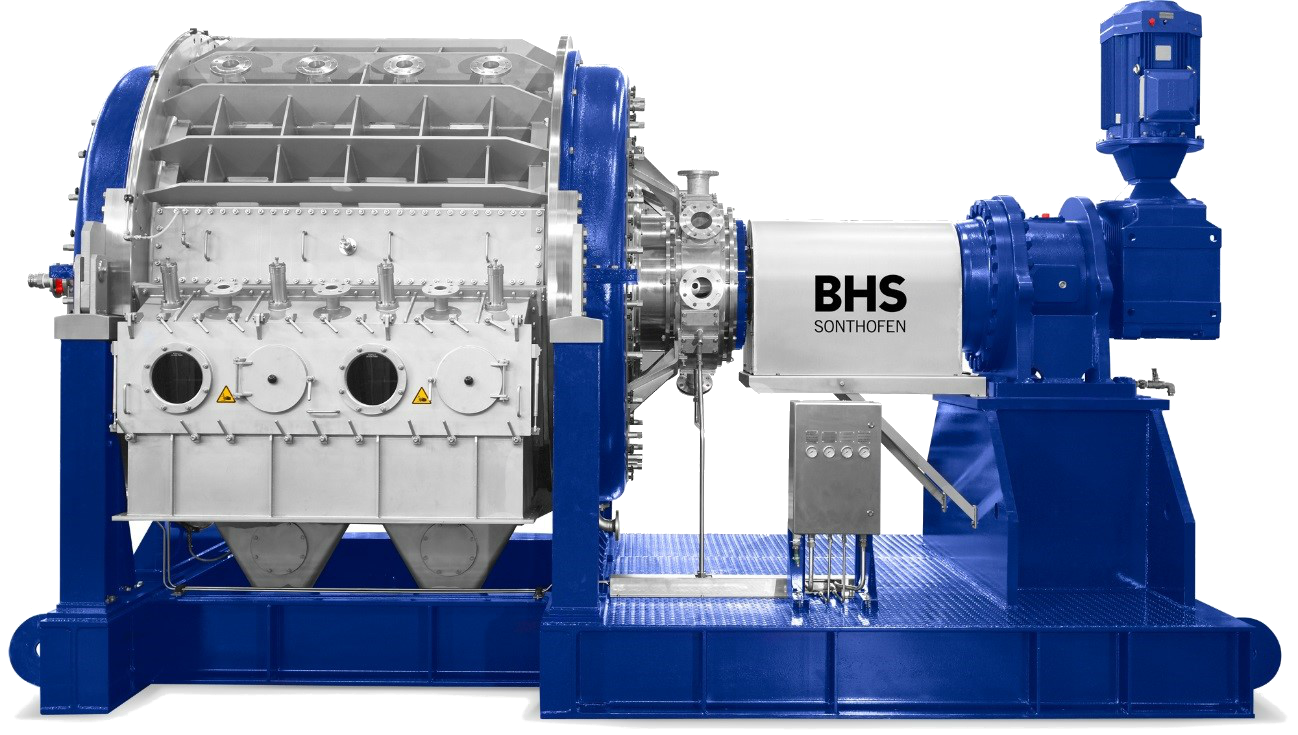

BHS Rotary Pressure Filter

Exclusive BHS equipment that combines the advantages of a rotary continuous filter with pressure operation to reduce implantation volume and increase performance and operational safety.

Its main features are:

This design is supported by more than 600 built-in rotary pressure filters with satisfactory operation. We have pilot units for demonstration of improvement performance against other technologies.

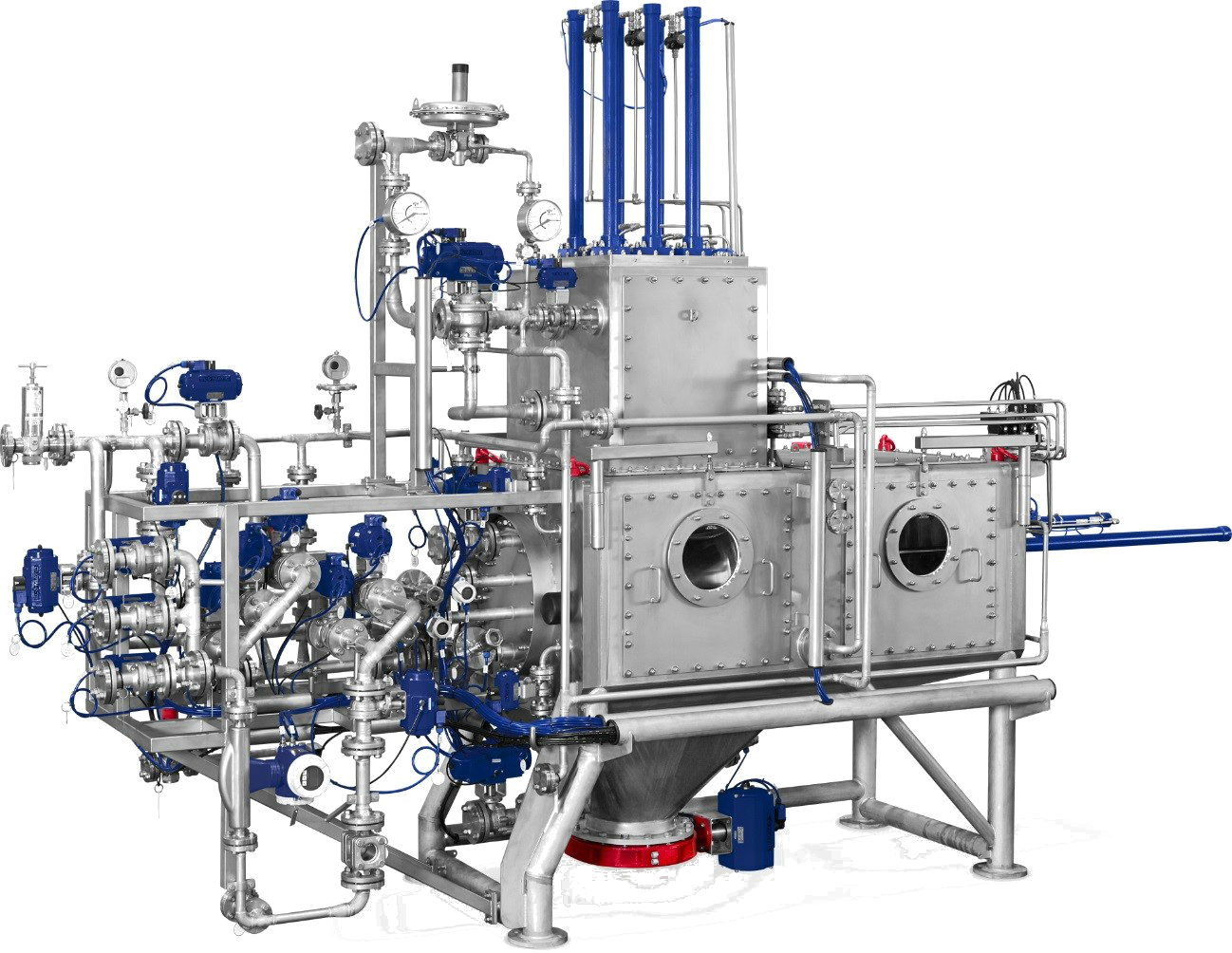

BHS Vacuum Belt Filter

Continuous filtration, washing and drying equipment, with customized configurations. Ideal for:

Its main features are:

BHS Pressure Plate Filter

For rapid filtration and clarifications in streams with low solids concentration (<5%):

Plate filters are used in applications similar to candle filter, although their differentiation is in use in applications where washing is required or whose cake is not sufficiently stable in vertical filtering surface. Applications of clarification and recovery of active carbons or catalysts.

BHS Candle Filter

Candle filters are ideal for rapid concentrations and clarifications of diluted streams, particularly with high volumes or flow rates. Possibility of batch and continuous operation with buffer tank for discontinuous automatic discharge. Typical applications with activated carbon, catalysts or any clarification

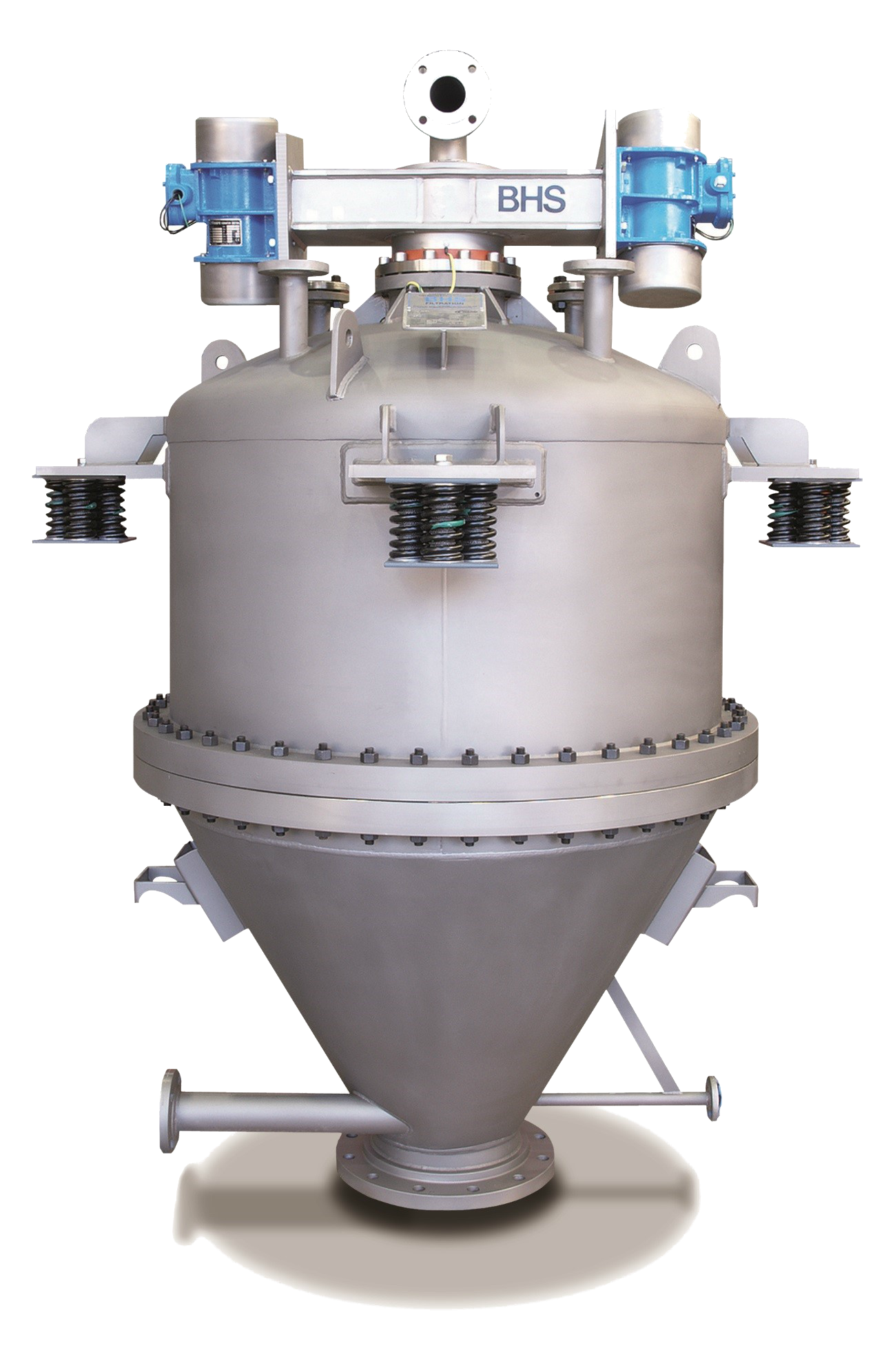

BHS Autopress

Unique equipment patented by BHS for the treatment of dangerous products, high added value or difficult filtration. Its typical applications are in the pharmaceutical sector (API filtration or HAPI filtration difficult, or recovery activated carbon in final product) or in chemical specialties. Its main features are:

We have test units for rent and compare performance versus other filtration or centrifugation solutions, which combine or do not dry in a single step. It has significant improvements in operating time, space used and no residual layer compared to Nutsche Filters or Reversible Centrifuges.