Broadbent was founded in 1864 concentrated on designing and manufacturing centrifuges.

Broadbent is structured in five Divisions, three of which support particular market segments. The remaining divisions are a dedicated service and support division for all types of centrifuge and a main manufacturing division that produces new Broadbent centrifuges.

SOLID BOWL DECANTER:

Decanter that is based on the principle of accelerating sedimentation by centrifugal force, with an internal scraper-helix that displaces the decanted solid and extracts it continuously.

The main features of the decanter centrifuge are:

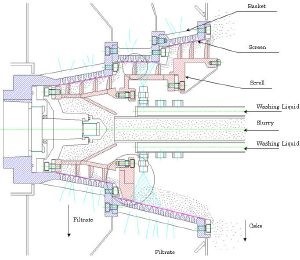

SCREEN BOWL DECANTER

The screen bowl decanter centrifuge is operationally similar to the solid bowl units, but it is designed to provide additional washing efficiency and enhanced moisture removal in applications where crystalline materials are involved. The screen bowl decanter operates in two stages, combining the clarification and sedimentation advantages of the solid bowl centrifuge and the de-watering benefits of an additional screen section. These centrifuges are typically used on BPA, some Minerals and Polyolefins.

SCROLL SCREEN CENTRIFUGE

The scroll-screen centrifuge consists of a horizontally driven scroll conveyor, which revolves at an optimum differential speed within a rotating conical basket. Solids separation from the mother liquor is achieved by the action of centrifugal force, operating at high g force, while discharge takes place via the inclination of the basket and the differential speed of the scroll. At the point of separation, solids are conveyed forwards by the scroll to discharge at the widest open-end of the filter basket, with the filtrate passing directly through the screen.

This type of centrifuge can be equipped with automatic scroll speed adjustment to accommodate changing process requirements, which completely eliminates operator intervention and process downtime. Scroll-Screen machines have an excellent washing capability and can be used for solids-liquid separation, where the feed materials have high particle sizes, i.e. 50 microns or above.