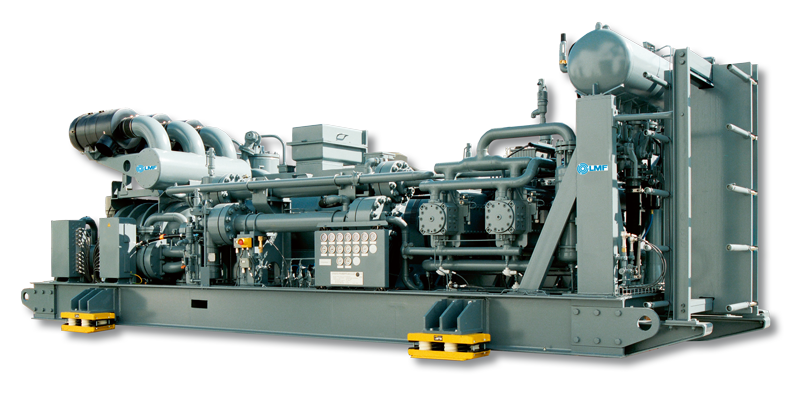

LMF is an Austrian manufacturer of gas compressors for industrial and oil & gas industry applications, in the power range of up to 6200 kW and for final pressures up to 700 bar.

LMF has over 166 years of experience and offers its customers the benefits of the latest developments in design engineering, proven manufacturing methods, full load testing prior to shipment, and superior after sales services.

The LMF product range, structured in a modular way, offers customs solutions to the needs of the client, both in technical and economic aspects. In addition, the careful selection of materials, as well as their manufacturing and know-how, guarantee optimal operation of the compressor equipment, even under the most adverse operating conditions.

Process gas compressors:

Compressors Seismic

Simultaneously with maximum efficiency and top availability the compressor systems used also guarantee minimal maintenance efforts as well as most compact dimensions and lowest possible weights. A rotary screw compressor is used to feed the piston compressor with pre-compressed air. Both compressors are directly driven by a centrally located electric motor or diesel engine.

LMF offers a comprehensive range of seismic compressors on capacities (FAD) ranging from 2 to 78 m³/min.

– 2 to 6 m3/min capacity:

air-cooled piston compressors designed for permanent operation.

– 8 to 25 m3/min capacity:

compact series: LMF proven compound compressor system in most compact light weight design.

– 31 to 78 m3/min capacity:

compound systems as optimal solutions for highest capacities with smallest possible space requirements and weights.

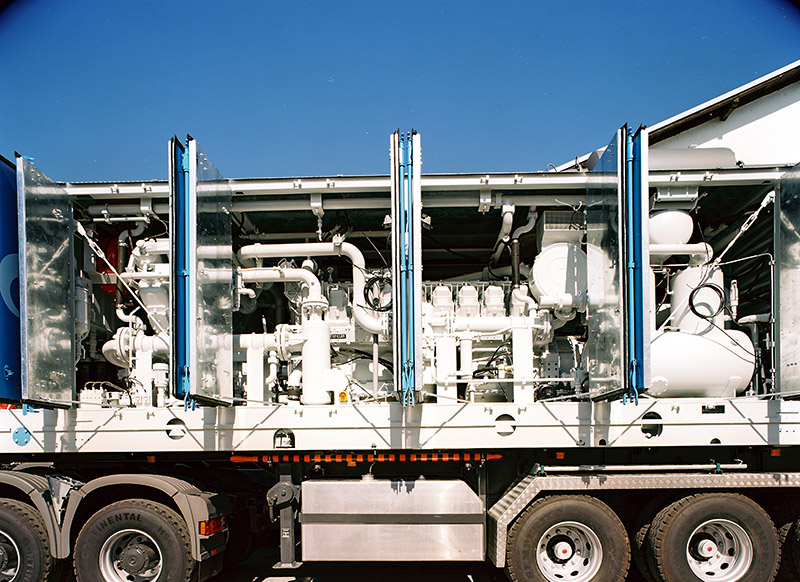

Mobile compression equipment for land and sea operation

With over 30 years of experience in the construction of mobile compressor systems for the oil and gas industry, LMF is the leading provider in this market segment worldwide.

Our 650 equipment that are operating, demonstrate day after day its reliability for first level operators from all over the world, under the most adverse working conditions, both in the field ´onshore` and in the ´offshore`.

Pipeline pressure testing:

LMF supplies fully automated self-sufficient compressor equipment for the evacuation of natural gas from gas pipelines, in the context of maintenance and repair measures. Through the use of LMF technology, the emission of gas into the atmosphere is minimized, in accordance with the objectives of the Kyoto Protocol, while taking advantage of the sale value of the gas evacuated.

On-site nitrogen production:

LMF supplies self-sustaining, fully-automated compressor systems for the production of nitrogen from ambient air, with a freely selectable purity between 90 and 98 %.

Gas pipeline evacuation:

LMF‘s patented two-stage operation is designed for maximum efficiency

in pipeline evacuation. Initially the system operates as a single-stage compressor for high volume operation, changing automatically to double-stage function during the second part of the evacuation process.

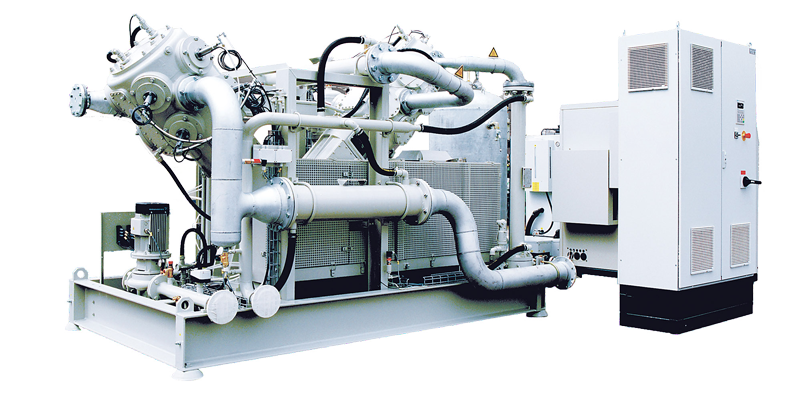

Oil free Eco-PET compressors

Compressor units in “V“ configuration with final pressure rates of up to 40 bar and power rates of up to 500 KW are available.

These compressors are largely used in PET bottle production.

Natural gas and bio-methane compressors:

Thanks to our well-engineered, modular GNC/GNV/CBG compressor and component systems developed and manufactured according to state of the art technology and compliant with the European and/or international standards and regulations, we are able to offer customized solutions for requirements and locations.

Today LMF is one of the leading companies worldwide in the field of GNC/GNV/CBG compressors.

.

The LMF production program for CNG / CNG compression stations in modular design covers all the usual performance requirements in the market:

Industrial compressors

These specially designed for high pressure air-cooled, for the compression of air and technical gases. These compressors are developed and manufactured in accordance with international standards.

The compressors can be designed for 2 up to 6 stages, as well as with 2 up to 6 single action cylinders.

The use of LMF compressors is not limited only to the following industrial areas of application: