PCI Membranes (a Filtration Group® brand) is a world leader in the custom-built crossflow membrane filtration systems for liquid separation using membrane technology, and has been manufacturing membranes and membrane systems for more than forty-five years supplying worldwide markets.

PCI Membranes is able to offer process solutions for a wide variety of filtration applications using microfiltration, ultrafiltration, nanofiltration and reverse osmosis technologies. PCI Membranes has developed expertise using all of the leading polymeric crossflow membranes and membrane configurations available on the world market and is therefore ideally placed to match a membrane to a specific application.

PCI Membranes’ open-channel membranes have the advantage of resistance to blocking and fouling by suspended or precipitate matter, with consequent minimal pretreatment requirements and ease of cleaning (PCI Membranes’ mechanical sponge-ball cleaning offers an alternative to chemical cleaning). With this broad product portfolio PCI Membranes selects the most appropriate membrane type to suit each application, minimizing investment and running costs and maximizing our customers benefits.

A series tubular membrane modules

The unique in-situ replaceable core enables fast, easy and cost-effective membrane replacement.

A5 series module

The module uses our specially developed PVDF Ultrafiltration membranes that are suited to a variety of different process conditions. Three different separations are available: 20k Daltons, 100k Daltons and 200k Daltons nominal cut-off, although actual performance depends also on the operating conditions.

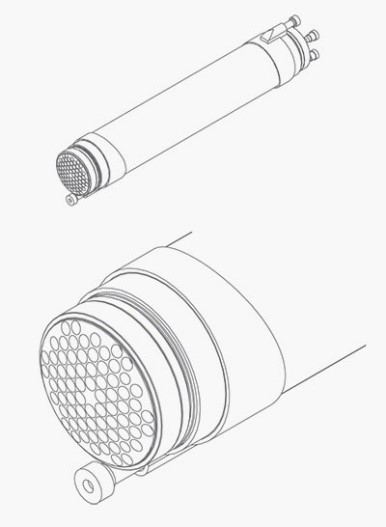

A19 series module

The A19 module consists of a replaceable core of 19 tubes each of 12.5mm diameter fitted into a stainless housing.

A37 series module

The A37 module consists of a replaceable core of 37 tubes each of 12.5mm diameter fitted into a stainless steel housing.

B1 series tubular membrane modules

The B1 module provides a robust proven housing for Ultrafiltration, Nanofiltration and Reverse Osmosis and can be fitted with a wide range of fully interchangeable membrane elements.

The open channel, highly turbulent flow design allows a wide variety of fluids to be processed, with minimal pre-treatment and permits easy replacement of membranes by the user. The design is also free of dead spaces reducing the fouling potential of the membranes while ensuring maximum effectiveness of cleaning-in-place procedures.

Due to the robust design, the module can be used in systems designed for operation at up to 80 bar at 80°C, dependent on the type of membrane fitted. The module is available as standard in 3.66m, 2.4m and 1.2m lengths, providing membrane areas of 2.6m2, 1.7m2 and 0.9m2 respectively.

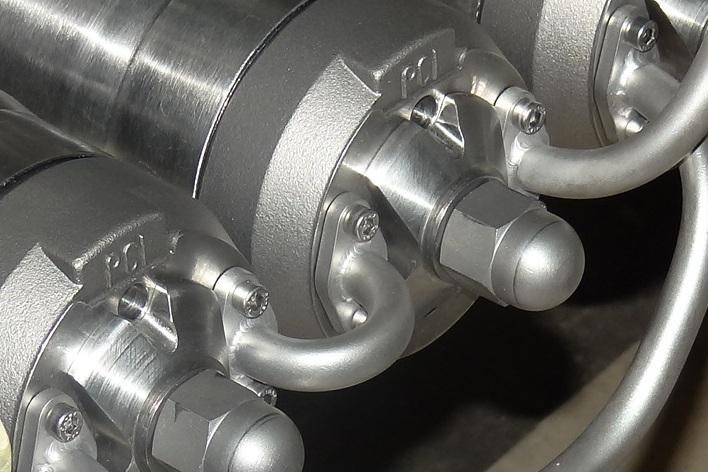

Flow of the process fluid through the tubes is effected by specially designed end-caps whose design varies depending on the process requirements – Series Flow, Twin Entry Flow, Parallel Flow.

Key features and benefits

series flow (RO) arrangement

For reverse osmosis systems the “series flow” module has channels molded in the end-caps connecting all the 18 tubes in series.

twin entry (UF) arrangement

For viscous materials an alternative end-cap type (known as “twin” or “double-entry”) is used which provides two parallel channels each of nine tubes in series.

.

parallel flow (UF) arrangement

The parallel end-caps allow all 18 tubes to operate in parallel allowing the highest crossflow velocities to be used with acceptable pressure drop. For less viscous materials the parallel end caps arrangement results in lower energy consumption.

C10 series tubular membrane modules

The C10 module provides economic use of a wide range of proven tubular UF and NF membranes and expands PCI’s range of tubular modules.

The module has been developed for process and wastewater liquid separations, as well as specialist municipal applications.

The design allows the use of tubular membranes in areas where they were previously considered uncompetitive against thin-channel membrane configurations.

The C10 module is provided as part of a module stack which includes support frame, manifolds and module connectors. A range of standard stack sizes and designs can cater for a variety of different duties and raw water types. Alternatively, stacks can be designed specifically to meet the need of individual applications.

The module can be used in systems designed for operation at up to 12 bar at 20°C, dependent on the type of membrane fitted. The module is available as standard in 3.66m, 1.8m and 0.9m lengths, providing membrane areas of 10.5m2, 5.2m2 and 2.6m2 respectively.

Test modules

While many applications can benefit from a more or less standard filtration system, other situations may demand a custom solution, with extensive process testing on-site. Membrane specialists can be expected to have experience and in-house expertise to provide solutions for filtration problems across a wide variety of industrial sectors and work with prospective clients to design and optimize a membrane filtration solution.

Before having a specialist determine the right membrane system for the application, it’s important to do some preliminary assessments to see if installing a filtration plant can be a viable proposition. Accordingly, some design criteria must be identified, such as:

Typically, a short pilot trial on site or in the supplier’s laboratory, using a sample of the process stream, will help narrow down the choice of membranes.

Next, a test rig or pilot plant is set up at the plant site. This will test the effectiveness of the chosen membrane system on a larger scale, utilizing up to 15 m2 (160 ft2) of total membrane area, and generate data useful in the development of final design parameters. These initial trials typically last for 2-3 weeks but can take longer if the waste stream varies in composition or volume over time. A well-designed testing procedure will save time and effort later.

With the test rig, engineers can take realistic measurements, including the degree of membrane fouling, the permeation rate (“flux”), the pressure drop, the retention levels as concentration increases, the effectiveness of the cleaning regime, and the quality of the end product.

From these data, the final system design is developed. In cases where a standard membrane is not suitable for the application in question, a new configuration of the membrane system may be needed. Also at this pilot stage, engineers can estimate the probable membrane life span, and this can be taken into account when considering the total lifetime costs of the system.

micro 240 & 960 series

The MICRO 240 & 960 are designed for economic, short-term evaluation of membrane processes for separation and concentration at laboratory bench scale.

A5 mini test modules

The A5 Mini Tester is designed for laboratory scale evaluation of Ultrafiltration membrane applications with moderate levels of suspended solids.

tubular membranes

Our in-house development and manufacturing capability enables us to provide customized membranes tailored for specific applications.

pilot units

The pilot unit is designed for pilot scale work and may be used to process a wide variety of aqueous solutions using Microfiltration (MF), Ultrafiltration (UF), Nanofiltration (NF) and Reverse Osmosis (RO).