With more than 100 years of experience in the design, manufacture and application of rotary tubular dryers and coolers, drum dryers and drum flakers for a wide range of materials, R. SIMON DRYERS Ltd can provide a unique advisory service for the process industry in the application of extremely efficient and duly proven products.

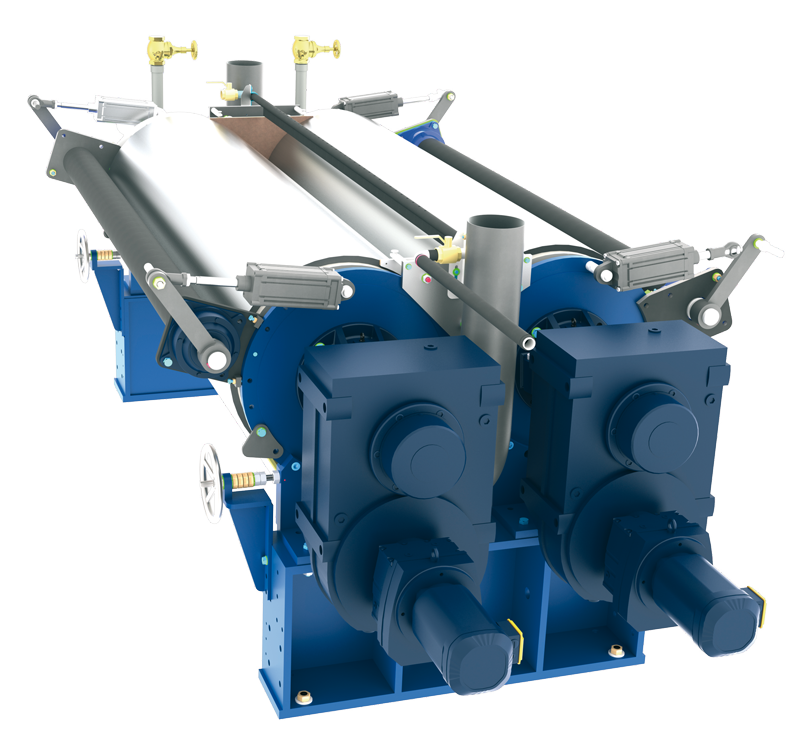

Drum dryers

The Simon steam heated Drum Dryer is noted for its high thermal efficiency in the removal of water and/or solvents from a wide range of solutions, slurries and suspensions.

The SIMON drum dryer is designed and built to provide many years of a service without faults. The core of the dryer is the drum, made of cast iron and designed to admit steam at high temperatures and high pressures. For those products that cannot be in contact with the cast iron, the drum can be chrome-plated on nickel for even more difficult process conditions.

Drum flaker

Over eighty years of experience in the design and manufacture of flaking equipment makes the Simon Drum Flaker the most effective single piece of process equipment for the conversion of materials from the molten or liquid state to easy to handle solid flakes in a single operation.

This change of state is achieved by applying a film of the material to be flaked to the outer surface of a horizontal rotating drum which is cooled internally by means of water, brine, glycol or any other suitable coolant. As the drum rotates, the liquid film solidifies and is subsequently removed from the drum surface by a doctor blade or knife.

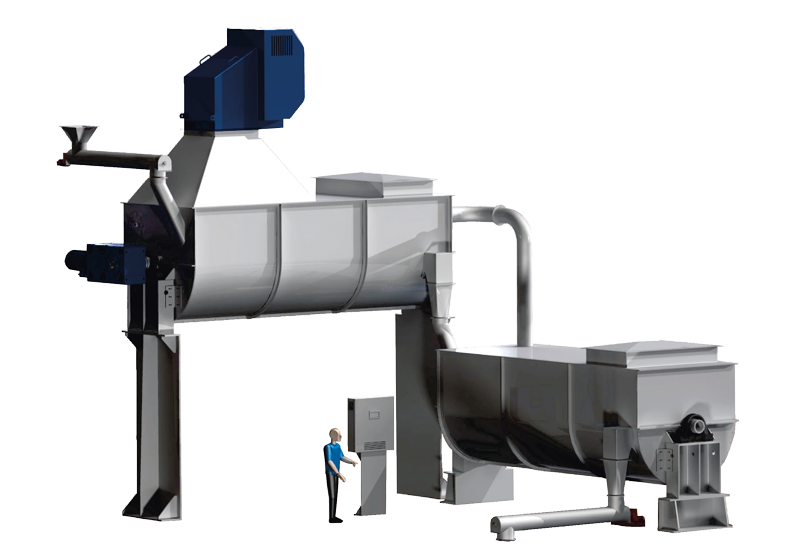

Tubular dryers

With over 100 years of experience in the design, manufacture and application of rotating Tubular dryers and coolers, for an extensive range of materials, R. Simon (Dryers) Ltd. can offer a unique advisory service to process industry in the application of extremely efficient and well proven products.

The drying is performed by a concentric rotating beam of parallel pipes, loaded with steam. The wet processed material is fed at one end of the machine passing over and between the tubes, being at the same time driven at a measured rate until it is discharged in the dry state at the opposite end. It is a continuous process. SIMON coolers have a very similar design, in which a coolant replaces the steam in the tubes.

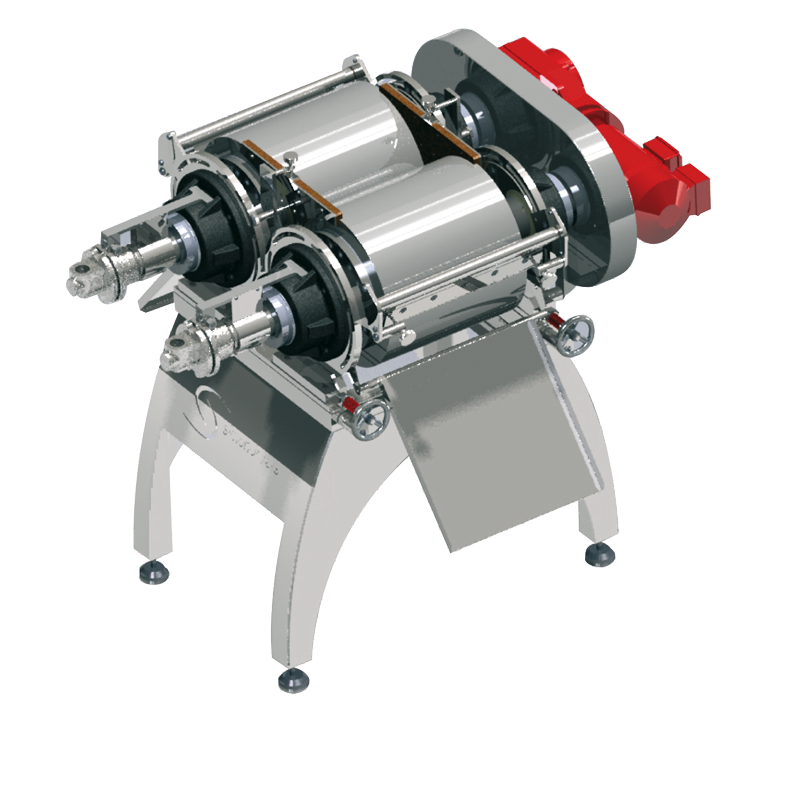

Lab dryers

The laboratory Drum Dryer is designed for food, chemical and pharmaceutical research.

The unit can be used for product development and educational use, ideally demonstrating the many drum drying and flaking applications to students. The equipment is supplied fully assembled and ready for connection to site services. Conversion to flaking operation can be achieved within minutes.

The design is fully interchangeable so that any configuration can be achieved by fitting the relevant accessory. The unit is constructed from stainless steel, providing cleanliness and resistance to chemical attack. The drums are cast iron and engineering hard chrome plated to ensure maximum heat transfer and the ability to scale up results to production sized equipment. The shaft mounted main drive speed is simply adjusted by electronic inverter in the control panel.