Sinergia is an industrial company specialized in the design and development of plants for the production, treatment, drying, filtration and separation of compressed air and technical gases. Over the years several product innovations have been introduced: adsorption systems, nitrogen generation, manufacturing of shell & tube heat exchangers, air coolers and screw compressors.

Oil free screw compressor

Oil free Screw compressors are used in a variety of air, process gas. Sinergia designs and manufactures high quality and innovative oil-free air and gas solutions for a wide applications’ spectrum. It offers a complete range of rotary screw air compressors that can meet any compressed gas requirements. All units are fully packaged ready to be hooked-up and are customizable in terms of heavy duty supplies severe, dangerous or explosive environmental conditions, ATEX, CE, ASME, API619, ISO 10440 compliance. They can be diesel or electric motor driven.

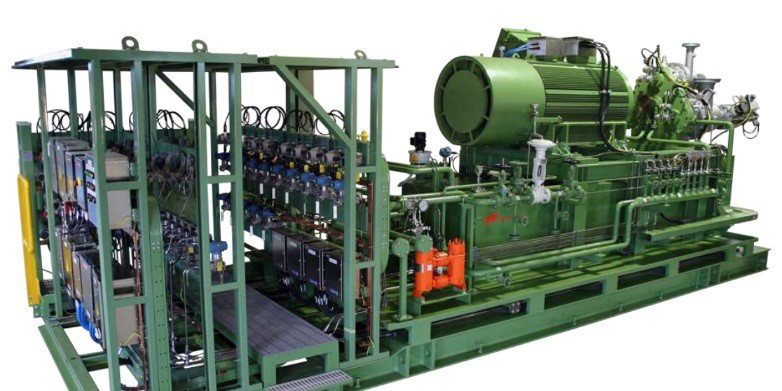

Centrifugal compressor

SINERGIA design and manufactures package with centrifugal compressors for air and process gas. All units are fully packaged ready to be hooked-up and are customizable in terms of heavy duty supplies severe, dangerous or explosive enviromental conditions, ATEX, CE, ASME, API672 compliance. They can be diesel, steam turbine or electric motor driven.

Oil flooded screw compressor

Oil Flooded Screw compressors are commonly used in a variety of air, process gas, process refrigeration and natural gas applications, including individual wellhead boosters, low pressure gathering systems, low stage boosters to existing reciprocating machines, solution gas and flare gas compression. Sinergia designs and manufactures high quality and innovative oil-injected air and gas solutions for a wide applications’ spectrum. It offers a complete range of rotary screw air compressors that can meet any compressed gas requirements. All units are fully packaged ready to be hooked-up and are customizable in terms of heavy duty supplies severe, dangerous or explosive environmental conditions, ATEX, CE, ASME, API619, ISO 10440 compliance. They can be diesel or electric motor driven.

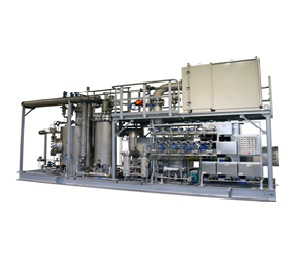

Cryogenic plant air separation

The air separation can be performed by means of cryogenic technology that liquefies the high quality compressed air stream and separates its elements through the distillation process. This system manages to supply gaseous nitrogen and oxygen and, if requested, small quantities of liquefied gases.

Oxygen generator PSA-VPSA

PSA technology can be used for Oxygen production too, by selecting a different molecular sieve. The process is exactly the same already described for nitrogen. VPSA technology is used in massive production of gaseous oxygen. High quality air stream is blowed at low pressure into molecular sieves placed inside two high capacity vessels. Regeneration of sieves is realized by means of vacuum generated by a pump. Alternative cycles of adsorption and regeneration assures continuous massive oxygen production at low pressure with high energy efficiency, caused by use of a blower instead of a compressor. If high pressure oxygen is needed, a booster integrate the process

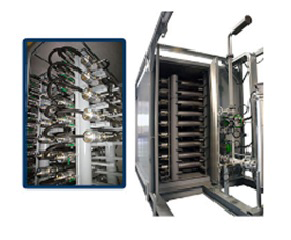

PSA nitrogen generator

PSA (pressure swing adsorption) is an alternative technology for air separation, able to produce a continuous stream of nitrogen by means of air filtration. High quality compressed air passing through carbon molecular sieves, placed inside two vessels, separates thanks to carbon porosity. Oxygen is adsorpted into molecular hollow, while nitrogen passes through and is collected as product of the process. Alternative cycles of adsorption and regeneration of carbons give continuity to production. Air pressure and timing of cycle’s control leads up with to requested purity.

Membrane nitrogen generator

High quality compressed air can be separated by means of membranes composed of synthetic hollow fibres. Their permeating walls let pass through water vapour, CO2, and oxygen, while residual gas, mainly nitrogen, goes along the fibers and is collected as product of the process. Thanks to air stream’s pressure and temperature control is assured maximum membranes performance in any ambience conditions. This leads up to requested purity with better energy efficiency.

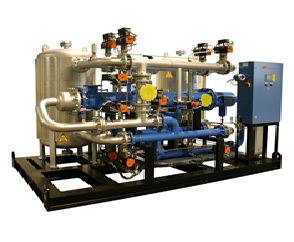

heat regeneration dryer

The regenerated dryers are a hybrid solution between heatless and hot regenerated dryers with external blower. The average dried air consumption in this case is approximately 7%. The operating times are generally halved compared to the hot regenerated dryers thanks to an exclusive system with a double air injection that optimizes the regeneration process. All units are fully packaged ready to be hooked-up and are customizable in terms of heavy duty supplies severe, dangerous or explosive environmental conditions, ATEX, CE, ASME, ISO7183 compliance.

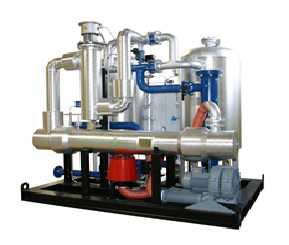

heat and blower regeneration dryer

Hot regenerated dryers with external blowers are normally used for large air flows and employ external heaters (electric or steam type) to perform the adsorbing material’s regeneration without any dried air consumption. All units are fully packaged ready to be hooked-up and are customizable in terms of heavy duty supplies severe, dangerous or explosive environmental conditions, ATEX, CE, ASME, ISO7183 compliance.

heat of compression dryer

Adsorption dryers with heat regeneration in closed circuit versions are based on physical process operating when air is being compressed. System will utilize the energy obtained for desiccant material’s regeneration (usually is alumina). The most important advantage of this dryer system is that doesn’t need external energy: these units don’t absolutely need purge air, electric heaters or blowers.

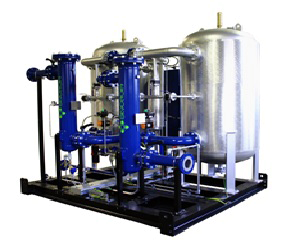

heatless dryer

The heatless dryers are the most commonly used devices for small and medium flows considering their simplicity and reasonable investment costs. Even though they are very essential devices, they are able to reach extreme dew points by means of a correct regulation of the regeneration time’s length and of the air quantity necessary at this stage. All units are fully packaged ready to be hooked-up and are customizable in terms of heavy duty supplies severe, dangerous or explosive environmental conditions, ATEX, CE, ASME, ISO7183 compliance.