The COMPANY Sulzer is the undisputed leader in the market for static mixing, heat exchanging and continuous reaction technologies. Its solutions are based in the experience provided by more than 70,000 references and the latest techniques in development, customer testing, CFD modeling, engineering and manufacturing to meet the clients processes requirements.

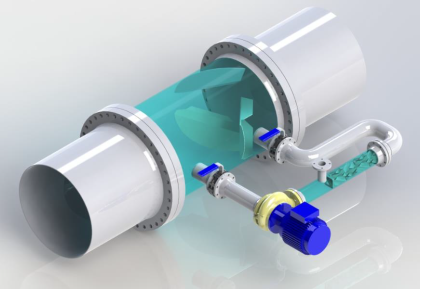

SULZER SMVTM AND MIXERS FOR TURBULENT REGIME

Specific designs for mixing, dispersion and contact for media transfer and reaction in turbulent regime, homogenization of low viscosity liquids and gases, introduction of additives. Availability of a wide range of materials, connections and tailor-made designs to guarantee homogeneity and minimum pressure drop.

WATER TREATMENT AND DESALATION

Sulzer CompaXTM is the optimal mixer for adding reagents in water with the minimum space requirement for installation and pressure drop.

The combinación of Sulzer SMVTMin by-pass and Suzler CompaXTM as a high-performance, is the most economical and compact solution for the dilution of gases such as CO2 for remineralization and pH adjustment.

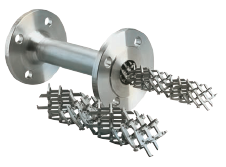

SULZER SMX plus ™ FOR LAMINAR REGIME

Mixing and homogenization in laminar regime of high viscosity products and with large differences in viscosity.

Dispersion of different phases with high viscosity differences, and gases in viscous liquids.

Specific designs for production of polyols and polyurethanes.

Specific sanitary designs for the food industry and mixing at low shear forces for shear sensitive products.

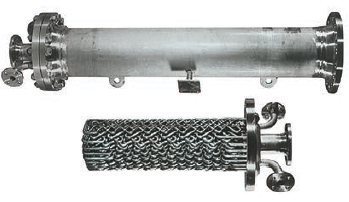

REACTORS AND HEAT EXCHANGERS

Designs of reactors and heat exchangers in continuous or semi continuous type SMRTM and SMXLTM by Sulzer for selective control of endothermic and exothermic reactions, average residence time and homogeneous temperature profile, piston flow. Non-aggressive treatment of products and media sensitive to temperature in cooling and heating processes. Improvement of heat transfer coefficients in tube exchangers for viscous and / or temperature sensitive products and shear.