VetterTec develops, designs, manufactures, installs and services a wide range of advanced drying and dehydration equipment, as well as complete dehydration, drying and compaction systems for customers in the main industries around the world

As part of the Moret Industries Group, it combines a total of more than 150 years of expertise and experience in evaporation, drying and dehydration equipment for the ethanol/alcohol, starch, brewery, vegetable oil, environmental and chemical industries.

VetterTec screw presses

VetterTec screw presses are used to remove water from products containing solids. The product enters to the pressing section through a feed hopper. In this section, the screw press compresses, removes and processes the product so that the water drains through the screen cage. At the end of the pressing section, the material falls through the discharge hopper thus exiting the press.

VetterTec screw presses are used in a wide range of applications. Mainly, they are used for the mechanical removal of water but also for washing the soluble parts of a product. For optimal operation, each press is specially adapted to your application. For this purpose, a design with conical or cylindrical shape can be chosen, the geometry of the screw is adapted, the perforation of the screen is optimized, the drive is designed, etc.

Tube bundle dryers

VetterTec tube dryers are safe and reliable equipment due to their mode of operation. The steam-heated tube bundle slowly rotates in an immobile casing and transports the product to be axially dried through the dryer. Some shovels elevate the product along the circumference and then the product flows through the tube bundle back into the channel. The product is dried by contact with the tubes and by convection.

VetterTec tube bundle heat exchangers are used in a wide range of applications such as dryers, conditioners or solvent eliminators. Both the granular as well as the slightly adhesive products can be dried in a tube bundle dryer. To dry lightly adhesive products, the dryer is equipped with a recirculation system specially developed for this purpose.

Flash and ring dryers

The VetterTec ring and flash dryers are ideal drying systems for drying filter cakes, fibrous materials, sludge and sludge. Based on the flash effect and the minimum retention time, these dryers have a minimum of thermal influence on heat sensitive products.

VetterTec ring and flash dryers are pure convection dryers and can be designed as dryers with direct or indirect heat. A stream of turbulent hot air dries the product while it is transported co-current in a continuous process. Rapid evaporation ensures that the temperature of the product remains as low as possible, ideal for heat-sensitive materials.

VetterTec flash dryers are used to produce fine grain or pulverized materials when short residence times are required.

VetterTec ring dryers are flash type dryers, which incorporate a centrifugal classification system to selectively increase residence time for wetter and larger materials.

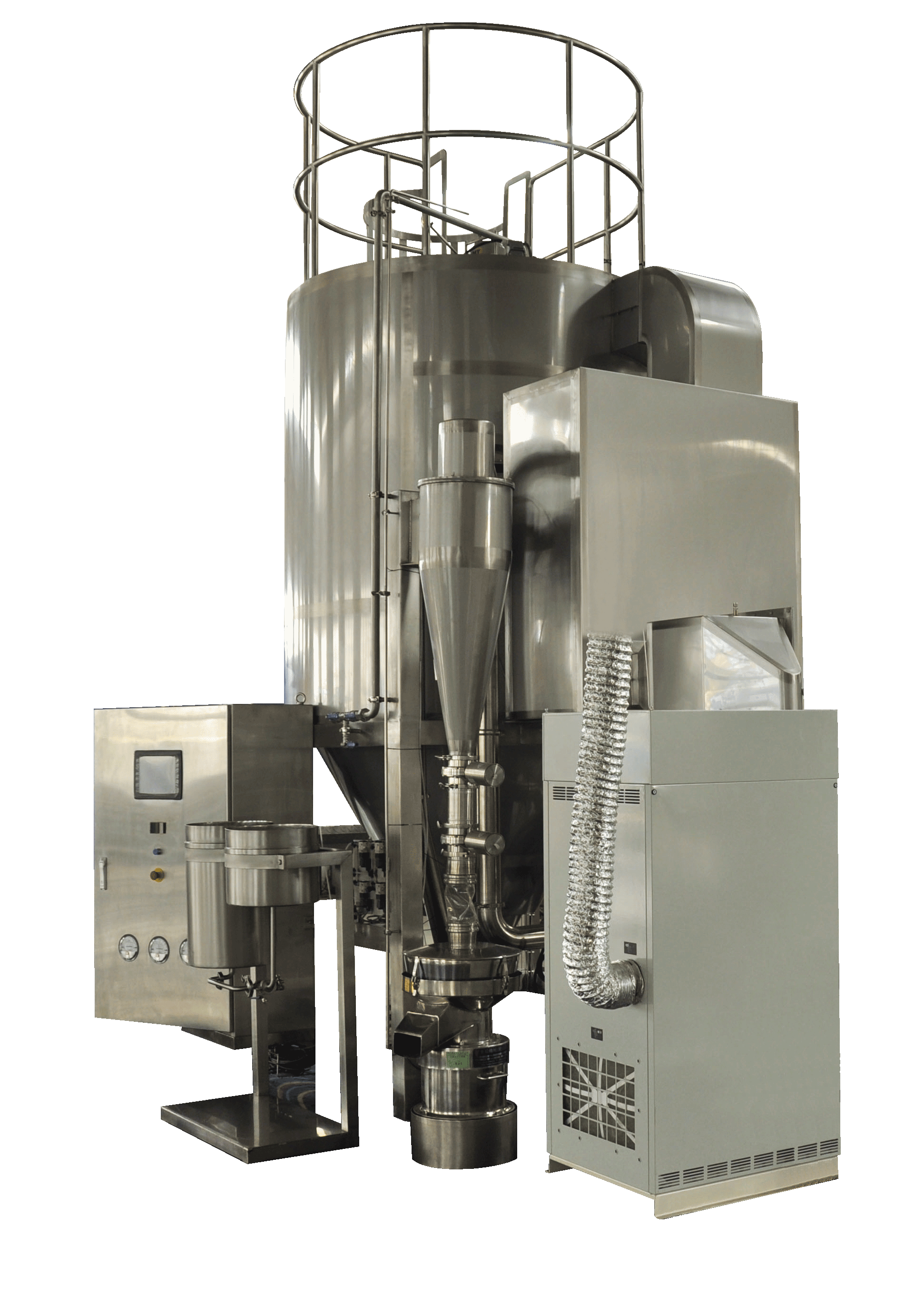

VetterTec spray dryers

VetterTec spray dryers are designed to dry powdered liquids through an atomizer in a high and efficient range. This very gentle drying is mainly used to dry heat-sensitive products. VetterTec is able to construct spray dryers from pilot plant scale to industrial units.

VetterTec spray dryers offer high design flexibility.

The atomization is provided by centrifugal wheels, pressure nozzles or two fluid nozzles. This range of systems allows to accomplish the specific particle size requirements for each application. Direct or indirect heating systems are supplied depending on the standards of the industry and each product.

Different drying chamber configurations are used along with a range of residence times, to provide the desired particle size and moisture content in the finished powder.

Possibility of obtaining agglomerated products through integrated fluid beds, fines recycling systems and external fluid beds. These powders are widely used in the food industries.