BORSIG Membrane Technology GmbH is an internationally successful company specializing in innovative concepts and products in the area of membrane technology and offering solutions for a broad range of industrial applications.

The objective of BORSIG Membrane Technology GmbH is to maximize the productivity of plants and, at the same time, to relieve the strain on the environment.

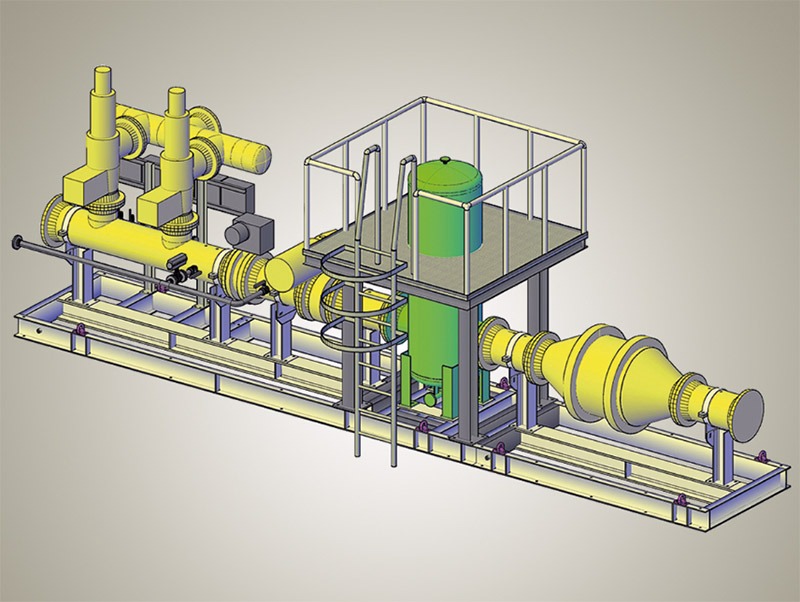

BORSIG Vapour Recovery Unit

The BORSIG Vapour Recovery Unit (VRU) combines absorption/condensation and membrane separation. The unit comprises a liquid ring compressor, scrubber column, membrane stage and vacuum pump.

.

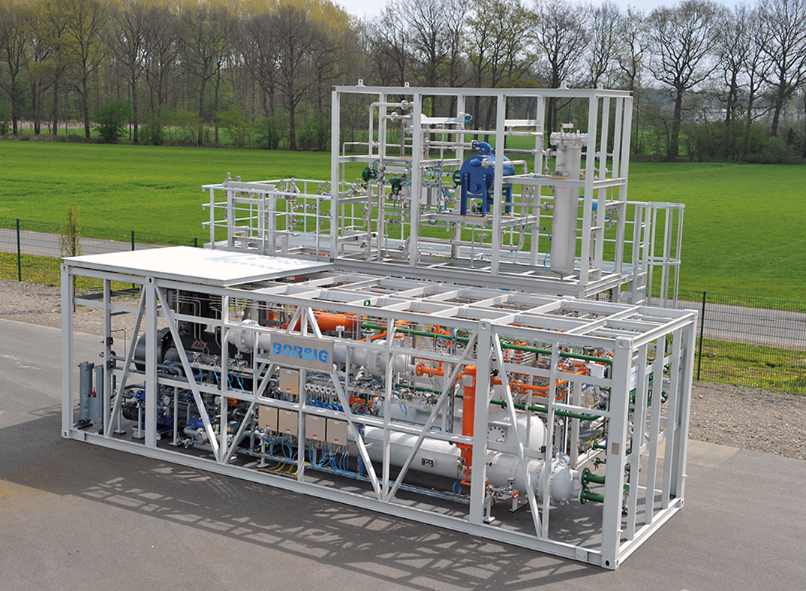

BORSIG Marine Vapour Recovery Unit

Next to the vapour recovery unit itself, the application of marine vapour recovery typically requires long piping installations and built-in safety devices e.g. dock safety units.

Very often the VRU is a minor part of the investment. The MVRU is able to handle single or parallel loading from one or various sea-going vessels.

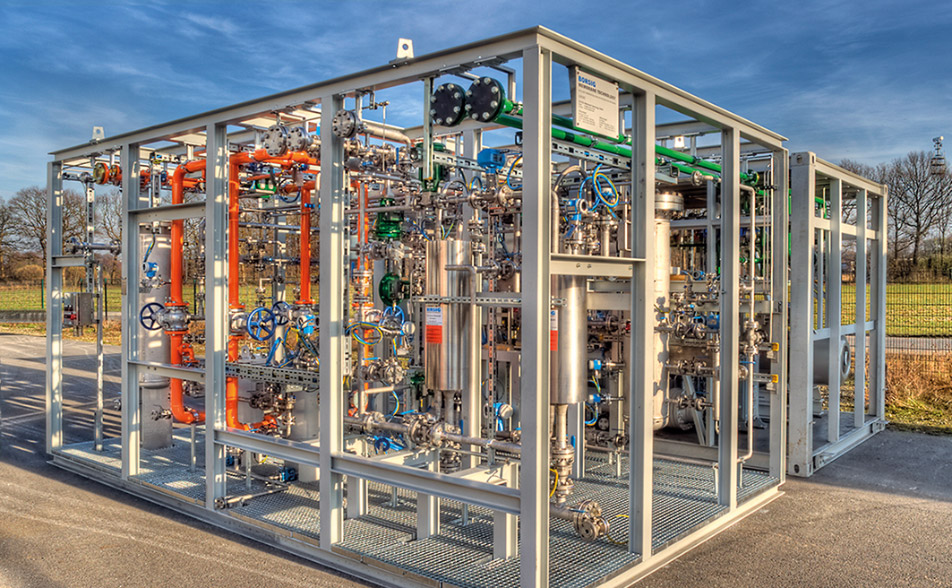

BORSIG Dock safety Unit

Marine loading installation and marine vapour recovery concepts in particularly require the comprehensive installation of hardware such as loading arms, vapour piping, VRU and additional safety devices.

The safety of this application must be safely implemented from the dock to the VRU. Over-filling, over/under pressure protection and fire and explosion protection must be considered.

BORSIG Membrane Technology GmbH offers compact, skid-mounted BORSIG Dock Safety Units for various capacities according to the latest safety guidelines.

As an integral part of the vapour recovery installation, this unit can be combined with the Vapour Recovery Unit to make a single vapour control system.

BORSIG Carbon Retrofit Unit

This unit reduces considerably of hydrocarbon mass flow to the carbon bed absorbers. A substantial mass flow of hydrocarbons bypasses the absorber vessels and directly enters the existing absorption system (scrubber).

BORSIG Vent recovery System

BORSIG Membrane Technology GmbH has developed an innovative, enhanced add-on system which increases the vapour return ratio from the car nozzle to the storage tank for more efficient vapour collection.

BORSIG Ethylene Recovery Unit

The BORSIG Ethylene Recovery Unit is an easy add-on system and can be considered for new and existing process installations.

BORSIG Propylene Recovery Unit

The BORSIG Propylene Recovery Unit is an easy add-on system and can be considered for existing and new process installations.

BORSIG Nitrogen Recovery Unit

For almost all polymer applications, nitrogen is used as purge gas stream or for drying purposes. As a result, nitrogen is mixed with hydrocarbons and cannot be reused. Our solutions for membrane processes (described above) are also designed for the recovery of nitrogen allowing a high recovery and purity of this, suitable for the reutilization.

BORSIG Fuel Gas Conditioning

The fuel gas quality is specified in terms of minimum methane content, methane number, dew point or calorific value or other closely related parameters.

BORSIG Hydrogen Separation

BORSIG Hydrogen Separation technology provides efficient and compact process packages based on highly selective hydrogen membranes. Tailor-made process solutions offer significant savings in hydrogen management for refineries and production plants.