EKATO is a group of leading companies in the development and manufacture of industrial agitators, reactors and mechanical seals, as well as mixing systems and dryers.

.

EKATO offers a wide range, from engineering services to the development and optimization of processes. Customized solutions for all branches of process-oriented industries. Based on a worldwide network of subsidiaries and service centers, with more than 600 employees, EKATO can guarantee the availability and operational reliability of its agitators and processing plants in the client’s company.

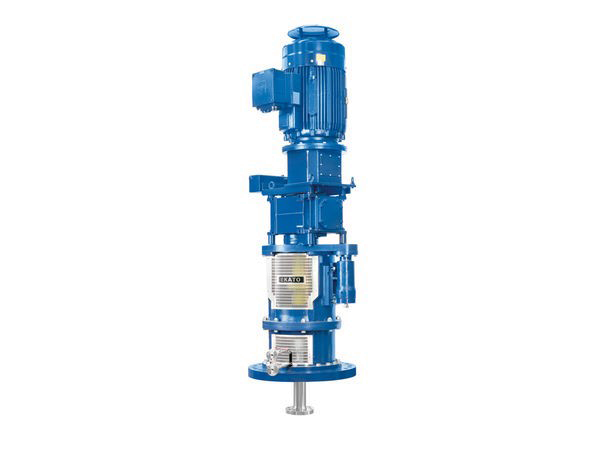

Agitators for HWL-N reactors

The agitators for reactors of the HWL-N type are the most powerful of the EKATO product range. We have already supplied large agitators with a drive power of up to 3,000 kW, shaft lengths of more than 15 m, as well as shaft diameters of 500 mm. These agitators have been designed to ensure maximum operational safety and comply with all valid DIN standards as far as possible. The robust design, as well as the easy and quick replacement mechanical seal, guarantee minimum maintenance costs and low operating costs

Drive versions with fixed or variable shaft speeds and different types of gearbox (flat, beveled, helical …)

Optional cast and welded flashlights

Quick replacement of the seal through system for this purpose (without the need to uninstall reducer and motor):

| Motor power | 5 – 3000 kW |

| Shaft diameter | 40 – 500 mm |

| Operating pressure | Vacuum – 200 bars |

| Impulse systems | High efficiency EKATO impellers and conventional impellers |

| Materials (wetted) | Carbon steel, rust and acid resistant steels, nickel-based alloy, Duplex and Super Duplex steels, titanium and titanium alloys, rubber coatings, coatings |

| Approval | ATEX 2014/34/EU y GOST TR-ZU 010/201 |

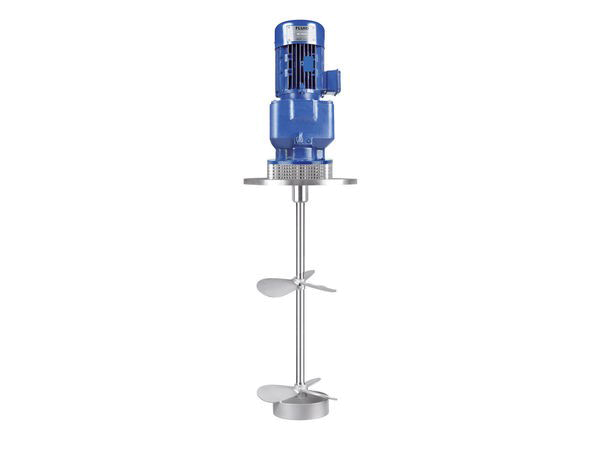

Industrial Agitators EM

EKATO agitators are designed for a wide range of volumes, and for pressurized or non-pressurized recipients. The unit can also be driven directly by an engine or together with a reducer. It is also possible to connect the motor via an IEC connector or a gearmotor. The shaft can be sealed by a mechanical seal or other types of seals.

| Motor power | 0,75 – 75 kW |

| Shaft diameter | 40 – 120 mm |

| Operating pressure | Vacuum – 12 bar |

| Impeller-systems | High efficiency EKATO impellers and conventional impellers |

| Materials (wetted) | Carbon steel, rust & acid resistant steels, nickel-base alloy, Duplex & super duplex steels, titanium, & titanium alloys, rubber coatings, coatings |

| Approval | ATEX 2014/34/EU y GOST TR-ZU 010/2011 |

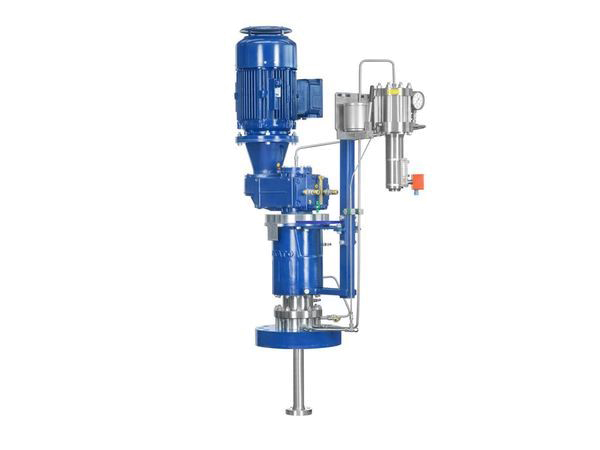

KOAX Coaxial Agitators

EKATO coaxial agitators are high performance units equipped with two universal impeller systems, each with an independent drive system. All types of mixing tasks that arise in the different stages of the process, such as homogenization, suspension, dispersion, heat transfer as well as solids decomposition can be combined and accomplish. This mixing system is preferred for complex processes and products with extreme viscosities and flow behaviors. Therefore, stages with different viscosities can be processed, from aqueous substances to 1 million mPas. KOAX agitators are a cost-effective alternative to mixers and extruders.

| Motor power | 5 – 250 kW |

| Shaft diameter | 40 – 220 mm |

| Operating pressure | Vacuum – 40 bar |

| Impeller-systems | High efficiency EKATO impellers and conventional impellers |

| Materials (wetted) | Carbon steel, rust- and acid resistant steels, nickel-base alloy, Duplex- and Super Duplex steels, titanium und titanium alloys |

| Approval | ATEX 2014/34/EU y GOST TR-ZU 010/2011 |

ESM Magnetic Safety Agitators

The EKATO magnetic safety agitator prevents leakage of the product by using a hermetic seal between the product and the environment, even when the agitator suffers some type of breakdown, which makes it the most suitable for mixing dangerous materials.

| Motor power | 5 – 200 kW |

| Shaft diameter | 40 – 100 mm |

| Operating pressure | Vacuum – 100 bars |

| Impeller-systems | High efficiency EKATO impellers and conventional impellers |

| Materials (wetted) | Rust- & acid resistant steels, nickel-base alloy, Duplex- & Super Duplex steels, titanium & titanium alloys |

| Approval | ATEX 2014/34/EU y GOST TR-ZU 010/2011 |

Compact Agitators FD/KD/HWL-A

The EKATO FD, KD and HWL compact agitators are available for open or with low pressure vessels. Its robust design and excellent softness when operating make them extremely reliable, even when mixing media with a high solids content. Other advantages are the low total height and the modular design that guarantees low cost maintenance and easy operator modification, if necessary.

| Motor Power | 0,75 – 400 kW |

| Shaft diameter | 40 – 800 mm |

| Operating pressure | Vacuum – 4 bars |

| Impeller systems | High efficiency EKATO impellers and conventional impellers |

| Materials (wetted) | Carbon steel, rust and acid resistant steels, nickel-based alloy, Duplex and Super Duplex steels, titanium and titanium alloys, rubber coatings, coatings |

| Approval | ATEX 2014/34/EU y GOST TR-ZU 010/2011 |

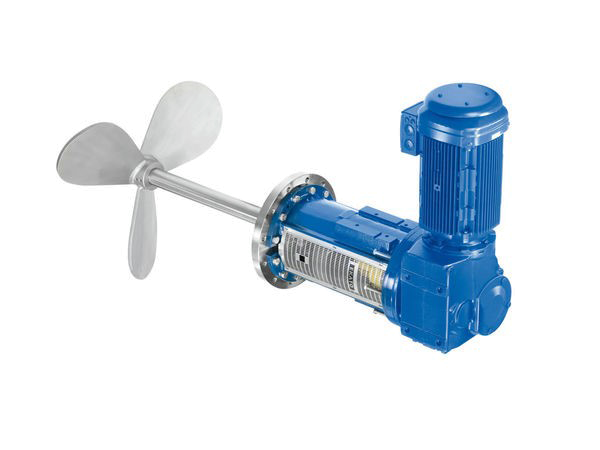

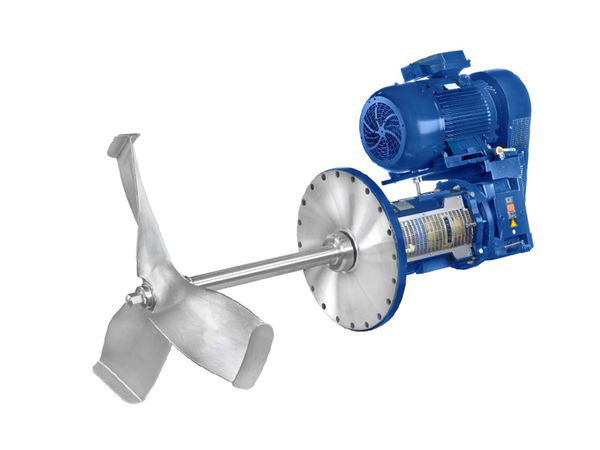

Side-Entry Agitators ES

EKATO ES agitators with mechanical seal are designed for side-entry installation in vessels of any size. The shaft is sealed by a mechanical seal.

| Motor power | 0,75 – 37 kW |

| Shaft diameter | 40 – 80 mm |

| Operating pressure | Atmospheric – 7 bars |

| Impeller systems | Propeller EKATO |

| Materials (wetted) | Carbon steel, rust and acid resistant steels, nickel-based alloy, Duplex and Super Duplex steels, titanium and titanium alloys |

| Approval | ATEX 2014/34/EU y GOST TR-ZU 010/2011 |

Side Entry for Storage Tanks ES-V

EKATO ES-V agitators with mechanical seal are designed for storage tanks of any size. The shaft is sealed by a lubricated mechanical seal of simple effect. The agitator is equipped with a device to ensure fast and easy maintenance or replacement of the seal, while the container is full. A new coupling design allows seal service without the need for any lifting equipment.

| Motor power | 1,1 – 15 kW |

| Shaft diameter | 40 – 60 mm |

| Operating pressure | Atmospheric – 3 bars |

| Impeller systems | Propeller EKATO |

| Materials (wetted) | Steels resistant to rust and acid, Duplex steels |

| Approval | GOST TR-ZU 010/2011 |

Single-acting lubricated mechanical seal ESD142

Mechanical seal with emergency operating characteristics

Lifting equipment is not required for seal maintenance

Do not disassemble the drive unit when the seal is maintained

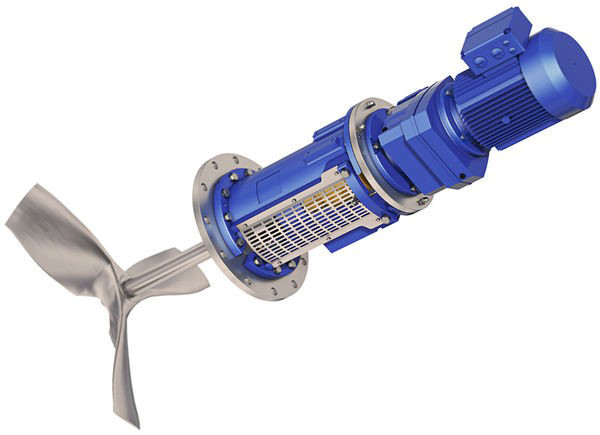

Side Entry Agitators for FGD HWL

The EKATO HWL FGD side entry agitator was specially designed to be used in absorption towers of flue gas desulfurization plants. Agitators are designed and manufactured for fatigue resistance, based on the rated power of the motor and the maximum dynamic loads. The side entry HWL-FGD is the world’s best-selling side entry agitator for absorption towers in flue gas desulfurization plants. The reliability of these extremely robust agitators is proven by more than 1,500 FGD plants.

| Motor power | 3 – 90 kW |

| Shaft diameter | 40 – 120 mm |

| Operating pressure | Atmospheric – 7 bars |

| Impeller systems | Propeller WINGJET |

| Materials (wetted) | Steels resistant to rust and acid, nickel-based alloy, Duplex and Super Duplex steel |

Different types of gearbox (trapezoidal, helical, conical belt …)

Mechanical Seal EKATO 42L: Lubricated single-acting mechanical seal for FGD agitators with side entry. This cartridge type mechanical seal is specifically designed for highly abrasive and corrosive media.

Closing device: The closing device allows maintenance of the mechanical seal, or even replace it completely, without closing or emptying the absorption tower.

EKATO Wingjet impeller: Developed specifically for use in absorbers for flue gas desulfurization. With its geometry optimized by CFD and its molded blades, this impeller offers the following advantages:

- Maximum efficiency

- Combined axial flow

- Increase in pumping capacity

- “Winglets” suppressing the tip vortex for reduced impact corrosion, longer operational life and reduced maintenance costs.

The impeller is built with Super Duplex materials, highly resistant to corrosion and abrasion.

Diameters available: 800 – 2000 mm

Allrounder Agitators MD/SD

The compact MD / SD standard agitators are the most versatile of EKATO. It is possible to make a connection of the motor through an IEC connector or a gearmotor.

| Motor power | 0,37 – 7,5 kW |

| Shaft diameter | 25 – 40 mm |

| Operating pressure | Atmopheric |

| Impeller systems | EKATO high-efficiency impellers and conventional impellers |

| Materials (wetted) | Carbon steel, rust- & acid resistant steels, nickel-base alloy, Duplex- & Super Duplex steels, titanium & titanium alloys, rubber coatings, coatings |

| Approval | ATEX 2014/34/EU y GOST TR-ZU 010/2011 |

Standard design

Drive version activated directly by the motor or together with a helical gearbox including a gear pin.

Agitators for small volumes FGL

EKATO FGL agitators are designed for small volumes and pressurized vessels. The unit can either be directly driven by a motor or together with a gearbox. A connection of the motor via IEC-adapter or a gear motor are also possible. The shaft is sealed by a mechanical seal.

| Motor power | 0,37 – 7,5 kW |

| Shaft diameter | 25 – 40 mm |

| Operating pressure | Vacuum – 7 bars |

| Impeller systems | EKATO high-efficiency impellers and conventional impellers |

| Materials (wetted) | Rust- & acid resistant steels, nickel-base alloy, Duplex- & Super Duplex steels, titanium & titanium alloys |

| Approval | ATEX 2014/34/EU y GOST TR-ZU 010/2011 |

- Drive version either directly driven by a motor or together with a gearbox

- Lantern made of stainless steel, also acting as seal housing

- Mounting flange/-plate

- Short heat trap

- Collector tray

- Shaft speed measurement

- Single-acting fluid lubricated mechanical seal

- Double-acting fluid lubricated mechanical seal

- Individual sealing liquids

- Sealing liquids and elastomers with FDA

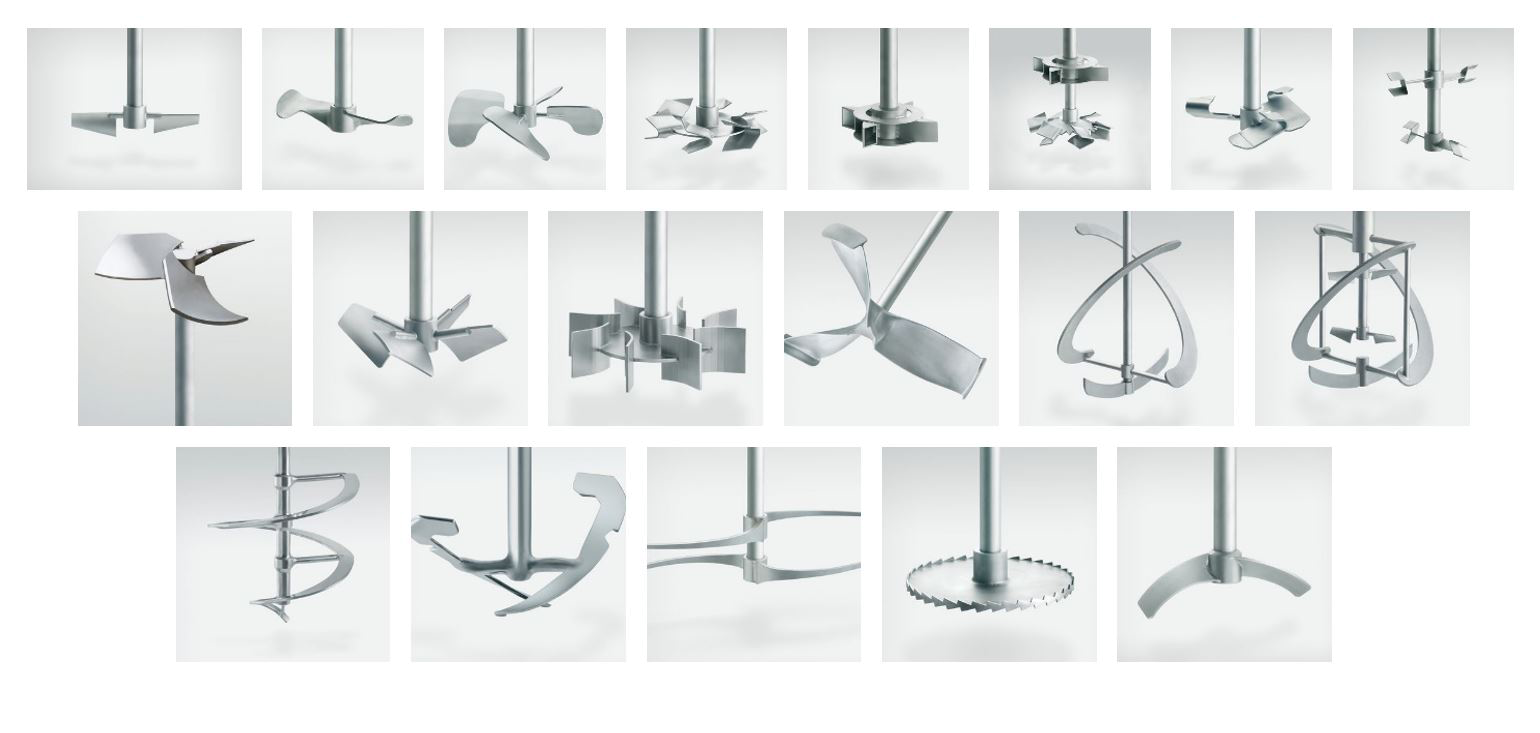

Impellers

Highly Efficient Impeller Systems Developed For Individual Requirements In Mixing Technology

In recent years, the requirements for mixing systems in industrial applications have increased steadily. The design of the impellers, the selection of a suitable mixing system, as well as the arrangement of the individual components on the agitator have a decisive influence on the process engineering and mechanical properties.

This not only applies to the agitators but also the reactors and their components. The comprehensive optimization of conventional impellers with industry-specific aspects was the basis for the development of the EKATO impeller family which is continually setting new standards in the field of mixing technology.

Hidrogenation plants

EKATO specializes in the design and engineering of hydrogenation plant technology, reliable development of a production process, and the mechanical design of hydrogenation plant equipment.

EKATO operates a Hydrogenation Test Center which has been designed to bridge the gap between bench-scale chemistry and commercial manufacturing. The flexible plant concept allows examining and optimizing your hydrogenation process with original raw materials under real operating conditions in pilot scale. The aim is to produce reliable test results for scale-up and development of a production process in an economical and timely fashion. Our engineering teams will apply the obtained knowledge for design of a full-scale hydrogenation plant which is tailored to your specific process requirements. Thus we pave the way for an efficient and risk mitigated investment in the new construction or the rebuilt of a hydrogenation plant.

EKATO will combine:

- Laboratory scale tests (5 liters) and pilot (50 liters)

- Hydrogenation reactor EKATO COMBINED GASSING SYSTEM

- Design and scaling both mechanical and process at industrial level.

- Security concepts

- Conceptual design of the entire plant

- Basic engineering

- Detail engineering

- Installation and commissioning

- Ingeniería de detalle

- Instalación y puesta en marcha

Mechanical Seals for Agitators

Wide range of seal technology for various applications

In mixing technology, the sealing of a rotating agitator shaft in the passage through a vessel wall represents the principal sealing task. Different sealing principles are used depending on operating conditions such as pressure, temperature, and speed.

Since 1950, mechanical seals have been used in agitator technology. EKATO is one of the pioneers in the use of mechanical seals in agitators and continue to produce them today.

In the sealing technology of EKATO, single-acting, double-acting, and triple-acting mechanical seals are used. A further distinctive feature is the type of seal lubricant. A distinction is made between dry running and gas- and liquid-lubricated mechanical seals.

Most mechanical seals of agitators consist of two rotating and two stationary slip rings (i.e., two pairs of slip rings). These pairs of sliding rings form a closed space, the seal chamber, which can be filled with a liquid, the seal liquid. By pressurizing the seal liquid, it is possible to ensure that the vessel contents are safely separated from the surroundings. When the seal chamber pressure is controlled to be always higher than the vessel pressure, the inevitable leakage of the seal liquid through the sliding surfaces can only enter the vessel or the surroundings via the sliding ring pair on the atmospheric-side. Conversely, the mixing product might not be suitable for the mechanical seal.

EKATO has a wide range of robust seals and reliable accessories for cooling and supplying the seal with seal medium. This makes it possible to flexibly perform sealing tasks and find the best solution for all sealing challenges. EKATO seals and their supply are thus always adapted to the specific application as well as the requirements of the customer.

Mechanical seals also have safety functions. EKATO therefore always tests the function of a sealing system before delivery. All the important operating data (e.g., speeds, temperatures, pressures, flow rates, filling levels, and leakage quantities of seal liquid and cooling water) can be continuously recorded electronically and submitted to the customer in the form of an inspection report.

This makes it possible to flexibly tackle sealing tasks such as:

- Tank temperatures from −60 to 400°C

- High pressures up to 200 bar

- Extreme sterility

- Batch/continuous operation

- Long service life

Accessories for mechanical seals

-

Collector tray

Sterile storage container with sterile installation

Pressure compensator

Cooling jacket – water jacket

Short heat trap

Temperature indicator

Flow indicator

Pressure indicator