Since Ferrum produced the first industrial centrifuges in 1935, the company has developed to a world-leading manufacturer of high-performance scraper and pusher centrifuges. Today, well-known producers from the chemical, fine chemical and pharmaceutical industries trust in the trouble-free solid-liquid separation of Ferrum centrifuges.

Series P:

Gypsum centrifuges VGC

Wet scrubbing processes are often used for flue gas desulphurisation FGD in coal fired power plants, waste incineration and cement plants. The gypsum generated by the FGD process can be washed and separated from the mother liquid by using gypsum centrifuges.

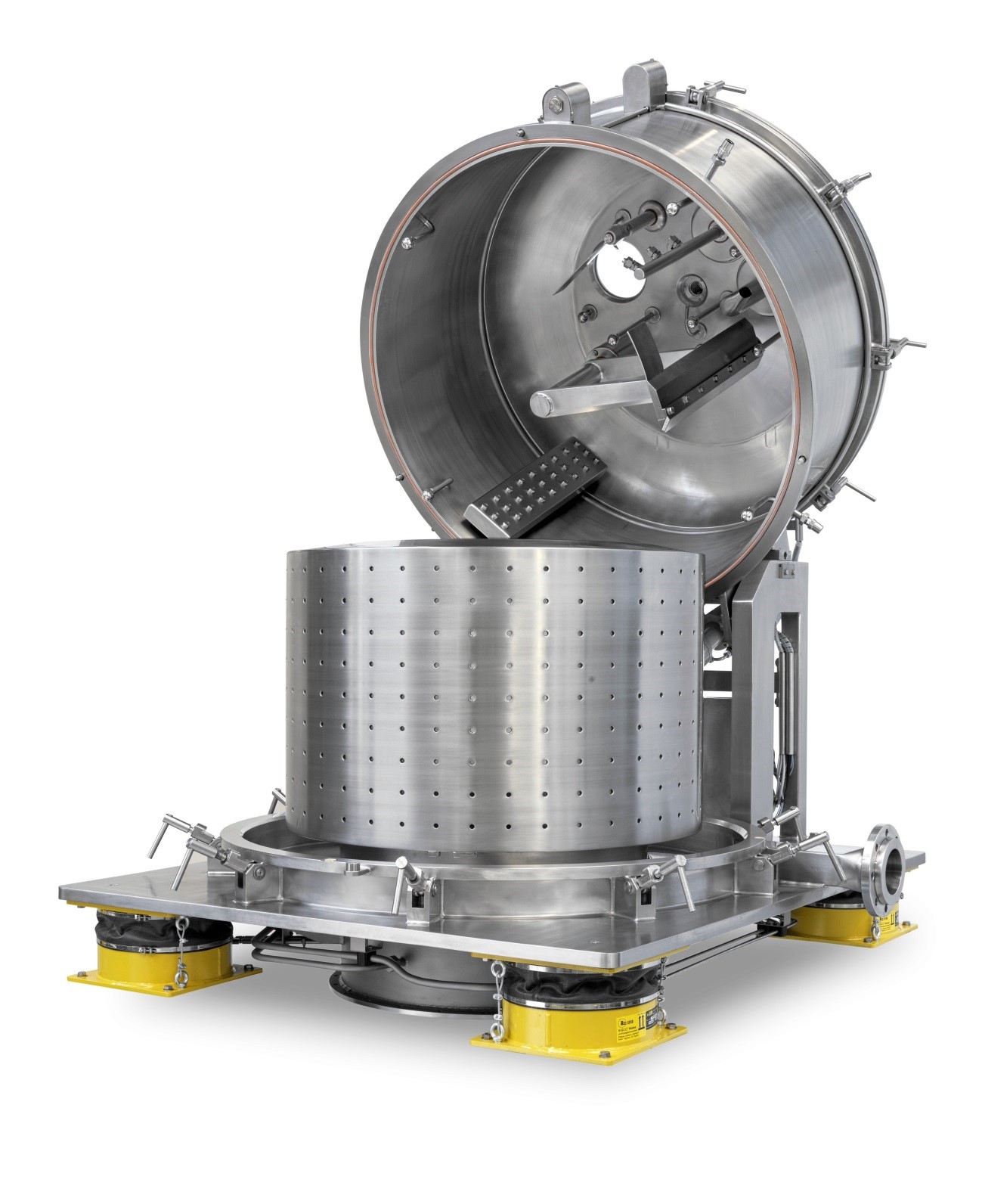

VTC type: Vertical discharge top centrifuges

The solids with top discharge centrifuges can be discharged vertically upwards manually, optionally using a filter bag and a lifting device or a special suction device. The applications range from pilot plants, small-quantity production to production applications in the chemical and pharmaceutical industries.

Serie VBC – Vertical Bottom discharge Centrifuge

The Vertical Scraper centrifuges VBC (Vertical Bottom discharge Centrifuge) include many application areas in the solid-liquid separation due to the modularity and the comprehensive range of optional equipment. The scraper centrifuges are used in the demanding continuous operation in the chemical and fine chemical industry or for complex pharmaceutical applications.

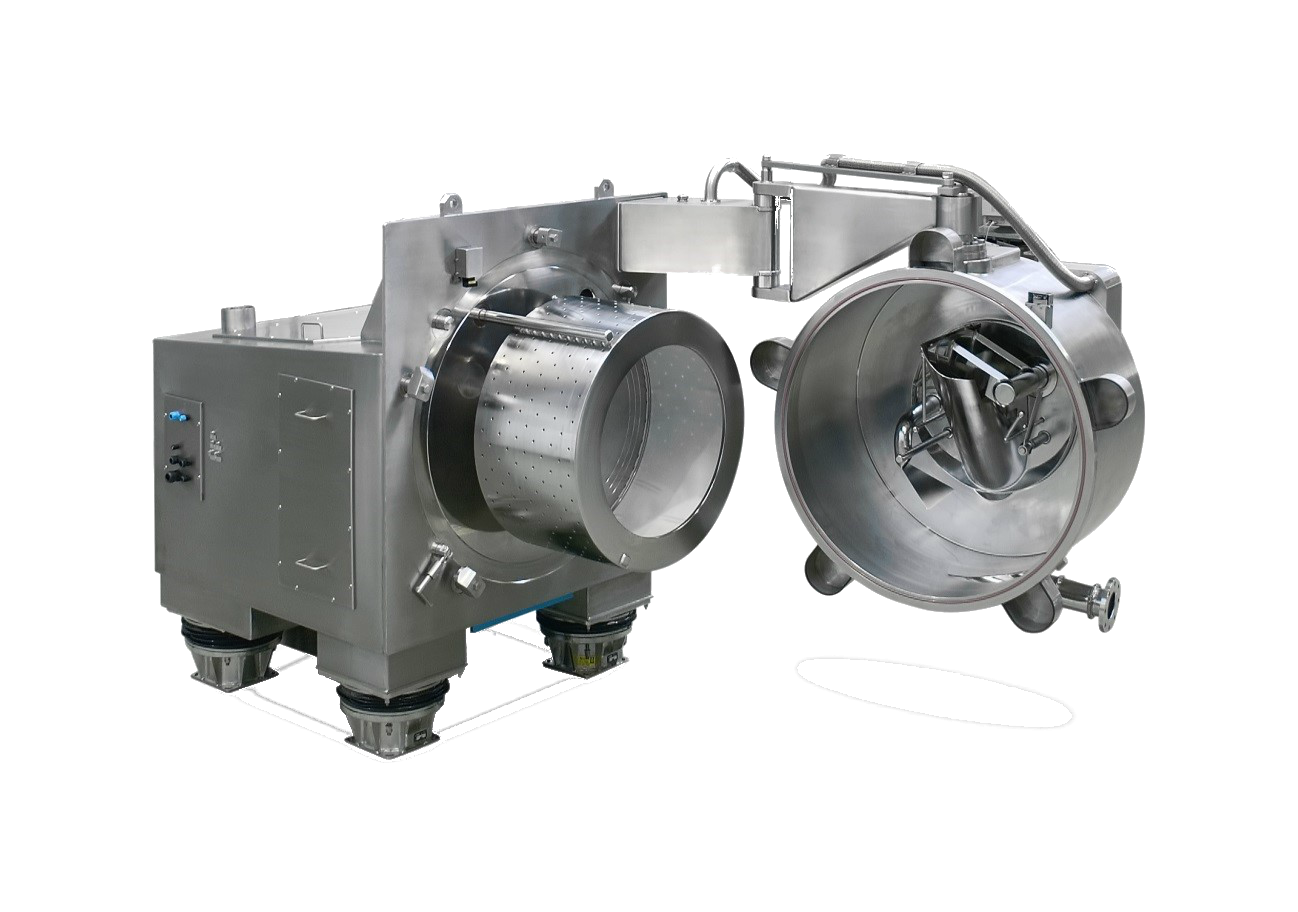

Serie HPZ: horizontal pharmaceutical centrifuges

The applications for pharmaceutical centrifuges HPZ range from pilot plants and low volume production to applications of production in the demanding pharmaceutical industry.

FERRUM has a Master Qualification Plan that includes all the necessary control points and documentation (DQ, IQ, OQ, PQ) for FDA certification.

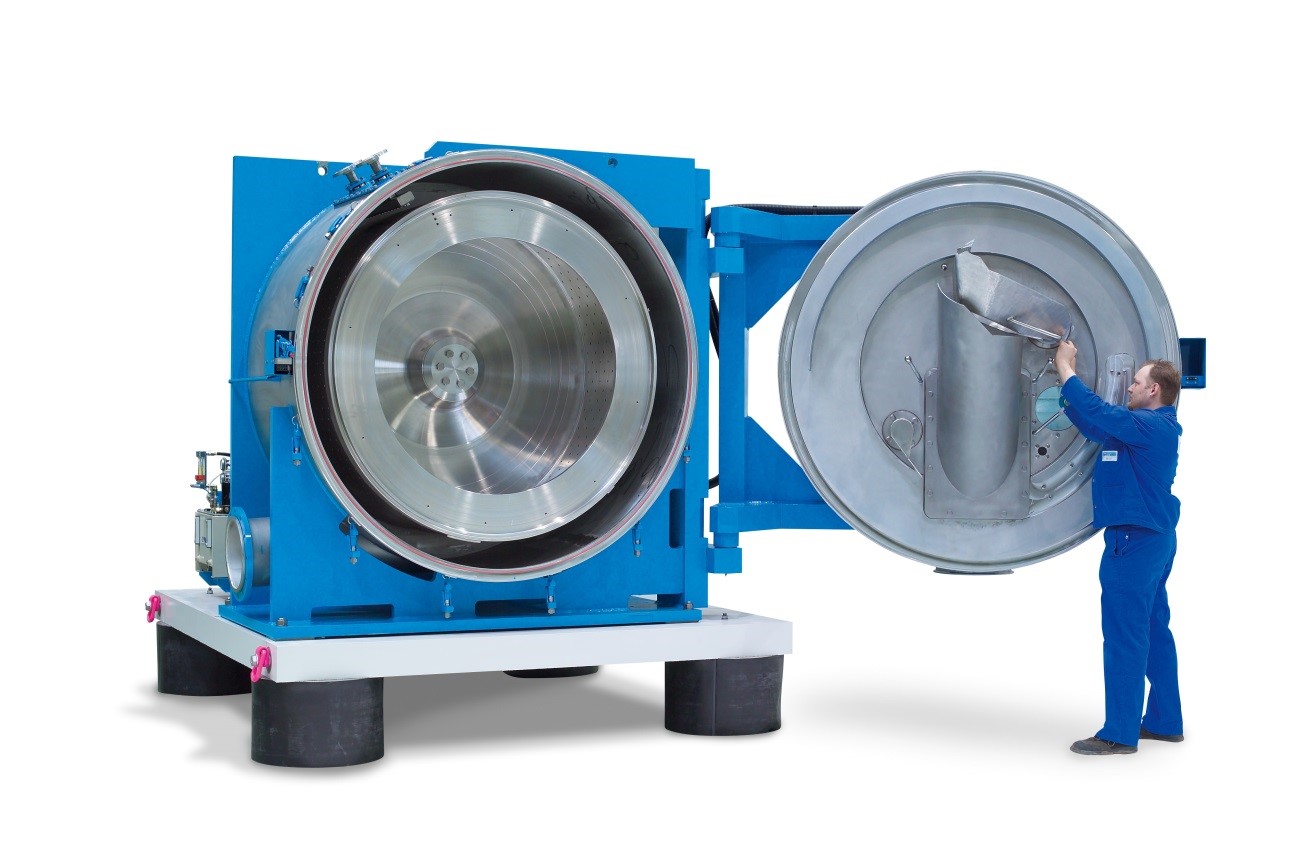

Serie HCZ: horizontal Chemical centrifuges

The horizontal chemical centrifuges were specially designed for high throughputs and continuous operation under the toughest conditions in the chemical and fine chemical industry.