For more than 70 years, Garo has been a world leader in liquid ring technology, providing compressors and reliable systems for the oil & gas, chemical and petrochemical industries.

Garo, as part of the Gardner Denver Nash division, it is able to offer a new level of worldwide sales, service and support through points of sale and Nash Certified ™ service centers around the world, while maintaining product manufacturing and systems from its plant in Monza, Italy.

GARO – Liquid ring compressors:

GARO liquid ring compressors are custom built for highly toxic, explosive and corrosive processes. They can handle dry and wet gases including ethylene, H2S (hydrogen sulfide) and many other condensable and non-condensable gases.

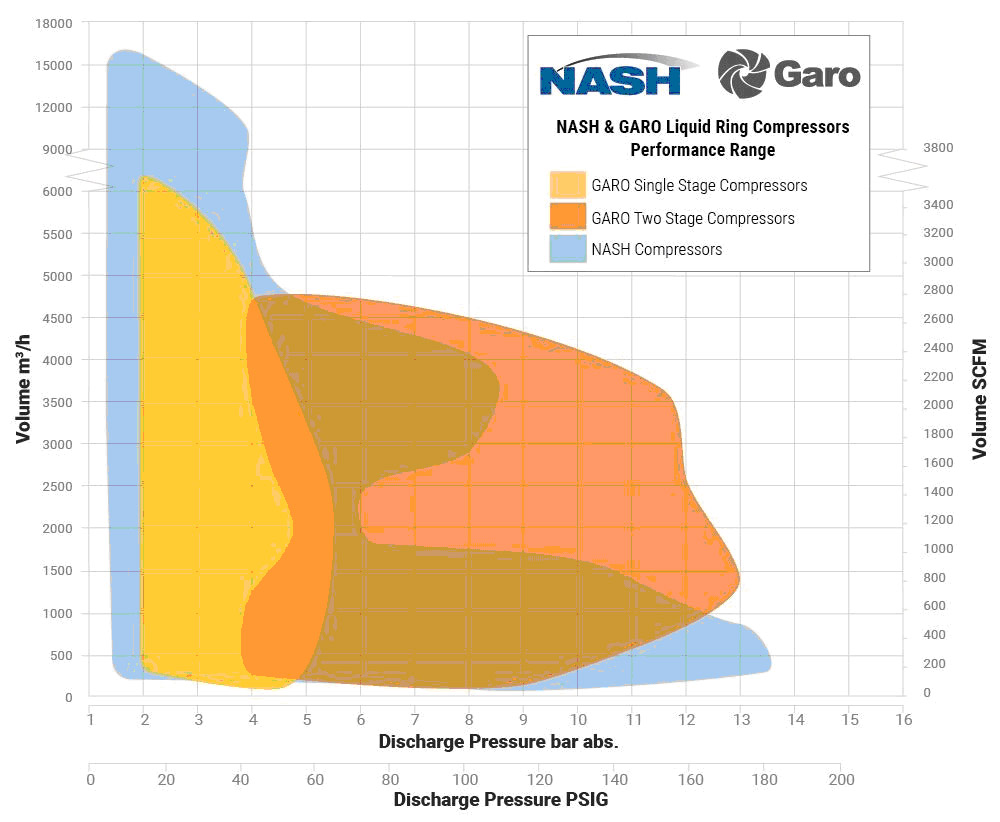

GARO AB – Two stages liquid ring compressors

GARO AB Two Stage Liquid Ring Compressors reach pressures up to 15 bar abs (200 psig) and are ideal for demanding process applications in petroleum refining and chemical plants.

GARO AM & ASM – Single Stage liquid ring compressors

GARO AM and ASM Single Stage Liquid Ring Compressors reach pressures up to 6 bar abs (72 psig) and are ideal for demanding process applications in petroleum refining and chemical plants.

Centrifugal compressors

GARO Centrifugal Compressors are custom designed for special applications that handling critical gases. GARO offers solutions to a niche market with a personalized approach and specialized design.

GARO Centrifugal Compressors reach pressures from 1.0 up to 12.0 Bar.g.

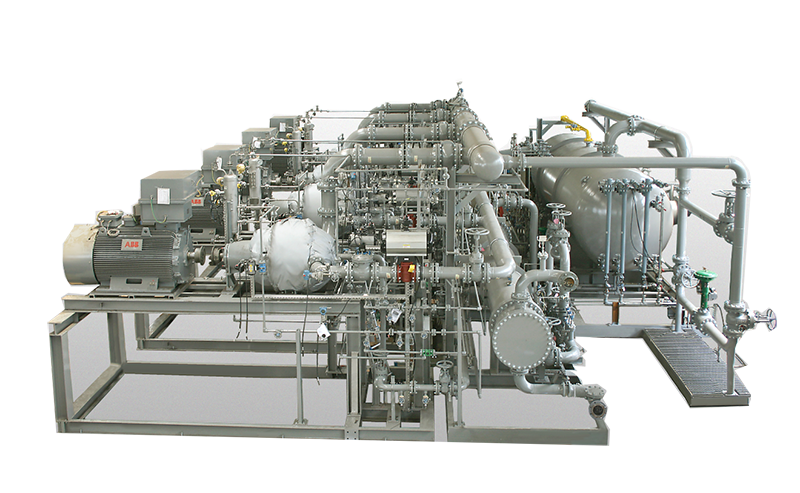

FLARE GAS RECOVERY SYSTEMS

GARO Flare Gas Recovery Systems count multiple global installations. GARO systems are recognized worldwide for their low maintenance operation and reliable performance while safely handling corrosive and toxic gases.

For more than 30 years GARO has provided complete flare gas recovery compressor systems that comply with environmental regulations and provide an immediate return on investment through the reuse of captured flare gas as valuable fuel or feedstock.

With a GARO Flare Gas Recovery System you can achieve near-zero flaring and reduce costly emissions while reducing unplanned downtime.

Pressure range: low pressure up to 5 Bar Abs Flow rate range: up to 5000 Am3/h per single compressor and high pressure up to 13 bar and 4000 m3/h per compressor.

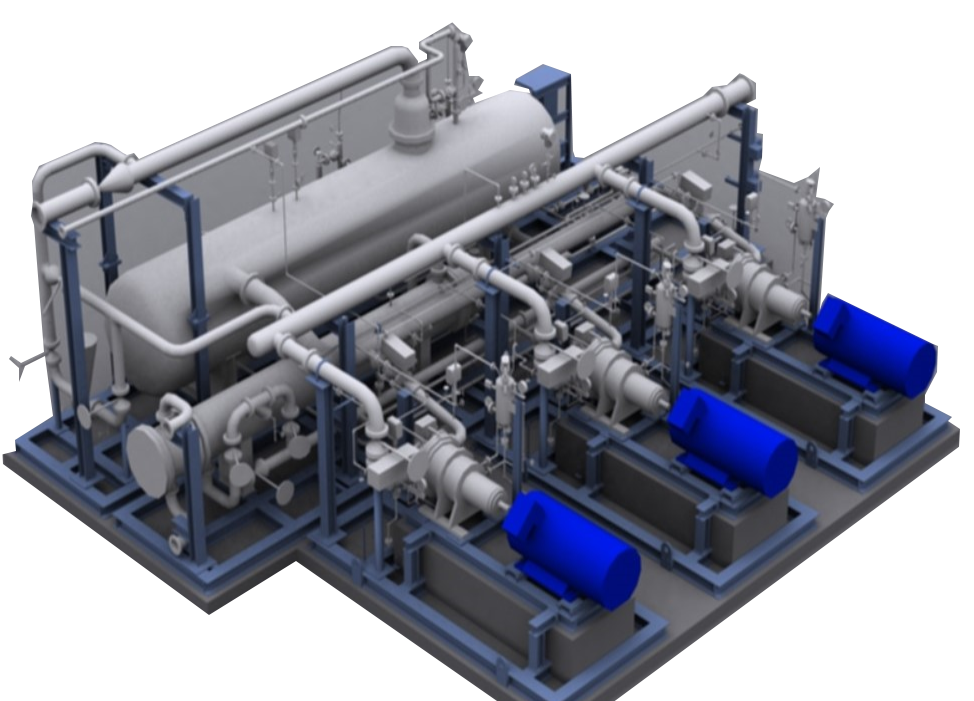

CUSTOMIZED PACKAGE SOLUTIONS

Our customized package solutions offer complete systems designs, built around reliable GARO liquid ring technology. From packages for flare gas recovery, to chlorine compression we custom design each solution for the challenges of demanding oil & gas and chemical applications.

GARO Customized Package Solutions comply with regional requirements, environmental regulations, while reducing cost and minimizing downtime.