Roots Systems LTD

Since 1974, Roots Systems Ltd has supplied blowers to leading process companies. Since then has accumulated extensive experience in the design and manufacture of blowers, handling a wide variety of gases in a wide range of applications and operating conditions.

As well as: Acid vapors, butane, oxygen, hydrocarbons, LPG, propane, hydrogen, nitrogen, chlorine, carbon dioxide, natural gas, VCM, sulfur dioxide.

Rotary-lobe Compressors

At the heart of each of our custom packages lies an oil-free rotary-lobe compressor. The rotary-lobe compressor is a variant of rotary-type positive displacement compressor.

Rotary-lobe compressors are typically known as ‘roots-type’ blowers or vacuum boosters, according to the situation in which they are used.

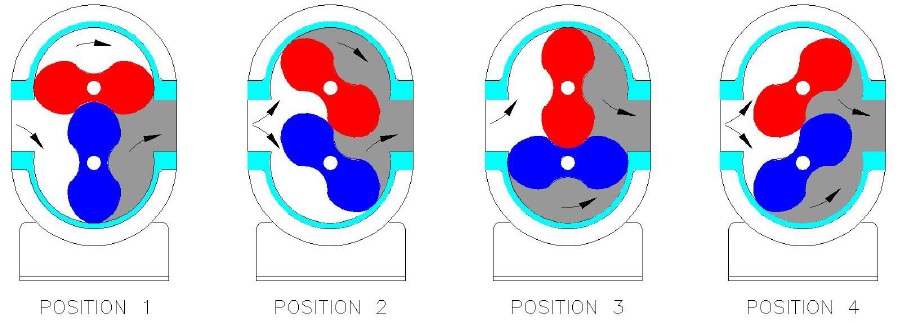

The rotary-lobe compressor incorporates two intermeshing rotors mounted on parallel shafts. In a twin-lobe compressor, each rotor has two lobes (four lobes per compressor). In a tri-lobe machine each rotor has three lobes (six lobes per compressor).

Principles of operation

- The two rotors rotate in opposite directions.

- As each rotor passes the blower inlet, it traps a definite volume of gas (the ‘displaced volume’) and carries it around the case to the blower outlet. With constant speed operation, the displaced volume remains approximately the same at different inlet temperatures, inlet pressures and discharge pressures.

- As each rotor passes the blower outlet the gas is compressed to the system pressure there and expelled.

- Small but definite clearances allow operation without lubrication being required inside the air casing.

- Timing gears control the relative position of the rotors to each other.