Ventilex is one of the leading global players in the drying of industrial products and is known for offering the highest quality and the highest energy savings in equipment of this type in the world.

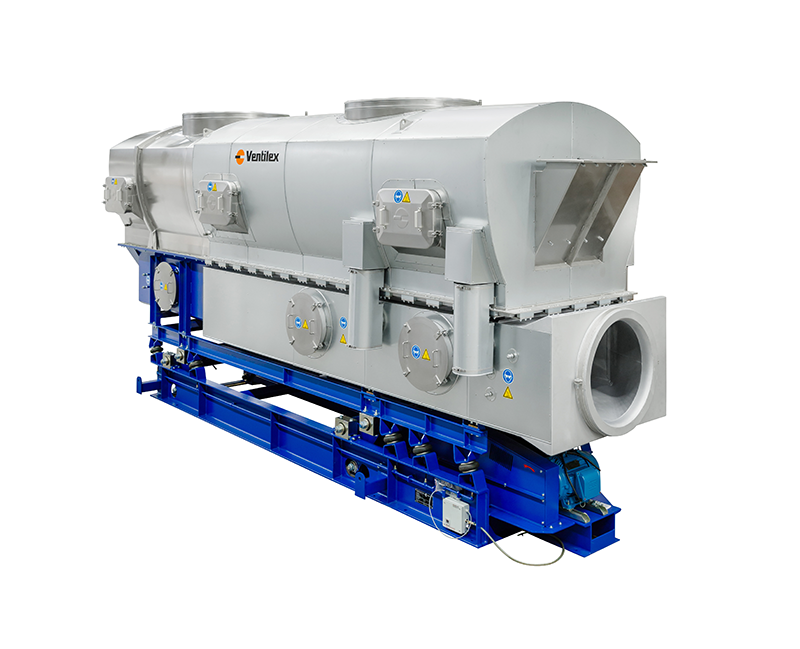

Drying and cooling using fluid bed technology

The range of fluid bed dryers from Ventilex was developed to satisfy the demand for processing high quality products at high production speeds with low energy consumption and associated production cost savings and low environmental impact.

In a fluid bed, a product becomes fluid by the action of an upward flow of gas. The mechanical movement of the fluid bed reinforces this effect. In this way, the gas and the product are mixed intensively and thus a high heat transfer and an optimum physical reaction speed are achieved.

The product is transported through the dryer by a smooth agitation movement. The low frequency / high amplitude of agitation guarantees a smooth and careful movement of the product. This guarantees negligible deterioration of the product, very low noise, and significantly reduced foundation requirements.

By choosing a good combination of gas velocity and mechanical movement, granular products with a wide variety of grain sizes can be successfully processed while a minimum amount of dust is formed.

Continuous Decontamination Systems

Ventilex decontamination systems are designed to decontaminate at high temperature and in a short time (HTST). The material is then dried and subsequently cooled.

The process works by feeding and discharging the product through a rotating self-cleaning valve that isolates the pressure autoclave from the ambient temperature. Inside this autoclave, a vibrating table transports the product through a pressurized steam chamber at a specific speed and creates a thin layer of product. Condensation remains on the surface of the product and this applies a high energy to the surface of the product. This kills bacteria and unwanted pathogens.

The time, the pressure, temperature and the steam inside the chamber are tightly regulated in such a way that the minimum amount of each required to kill the desired bacteria is applied. Subsequently, in the dryer the temperature is controlled so that the product is at a precise humidity level.

Belt dryers

Ventilex belt dryers are highly efficient and have low energy consumption. The combination of temperature cycles and drying times can be adjusted as necessary to control the physical properties of the final product. The internal transport consists of one or more stainless steel tapes. Because the drying air flows through the belt, the heat exchange is complete and results in high production efficiency and exceptional final product quality.

The raw material is evenly distributed through the conveyor belt by means of a suitable auxiliary mechanism, such as a distributor, a vibrating belt, a sprayer, or granulator. The drying tunnel is divided into zones, each maintaining a different temperature. Each zone has a system of air heating and recirculation, and if necessary, a system of extraction of humid air. As the conveyor belt passes through each zone, hot air passes through the material from top to bottom, then bottom to top, to produce a uniformly dry product.

Depending on the product, the tunnel may be equipped with a cooling section and a vibration device at the output to lower the temperature of the final product for convenient and timely packaging.

DryGenic: Air dehumidification systems

DryGenic dehumidification systems are used to provide fresh, dehumidified and decontaminated air for certain processes and / or process rooms.

The DryGenic principle of dehumidification is based on the drying properties of a hygroscopic liquid solution called Drysol. A DryGenic dehumidifier can supply air with a relative humidity from 20 to 50% RH. You can easily get low dew points, such as -30 ° C.

The DryGenic dehumidifier is a flexible system. The temperature and humidity of the air are controlled simultaneously in the process. Pre-cooling, post-cooling and post-heating of the air are not normally required.

These systems are specially designed to use low energy levels and minimize the total energy consumption. The DryGenic system keeps the air at a constant and precise humidity, regardless of weather conditions or load variations.

The use of a DryGenic air dehumidification system usually results in substantial savings in operating expenses of the plant and investment in refrigeration equipment.